Agricultural machines

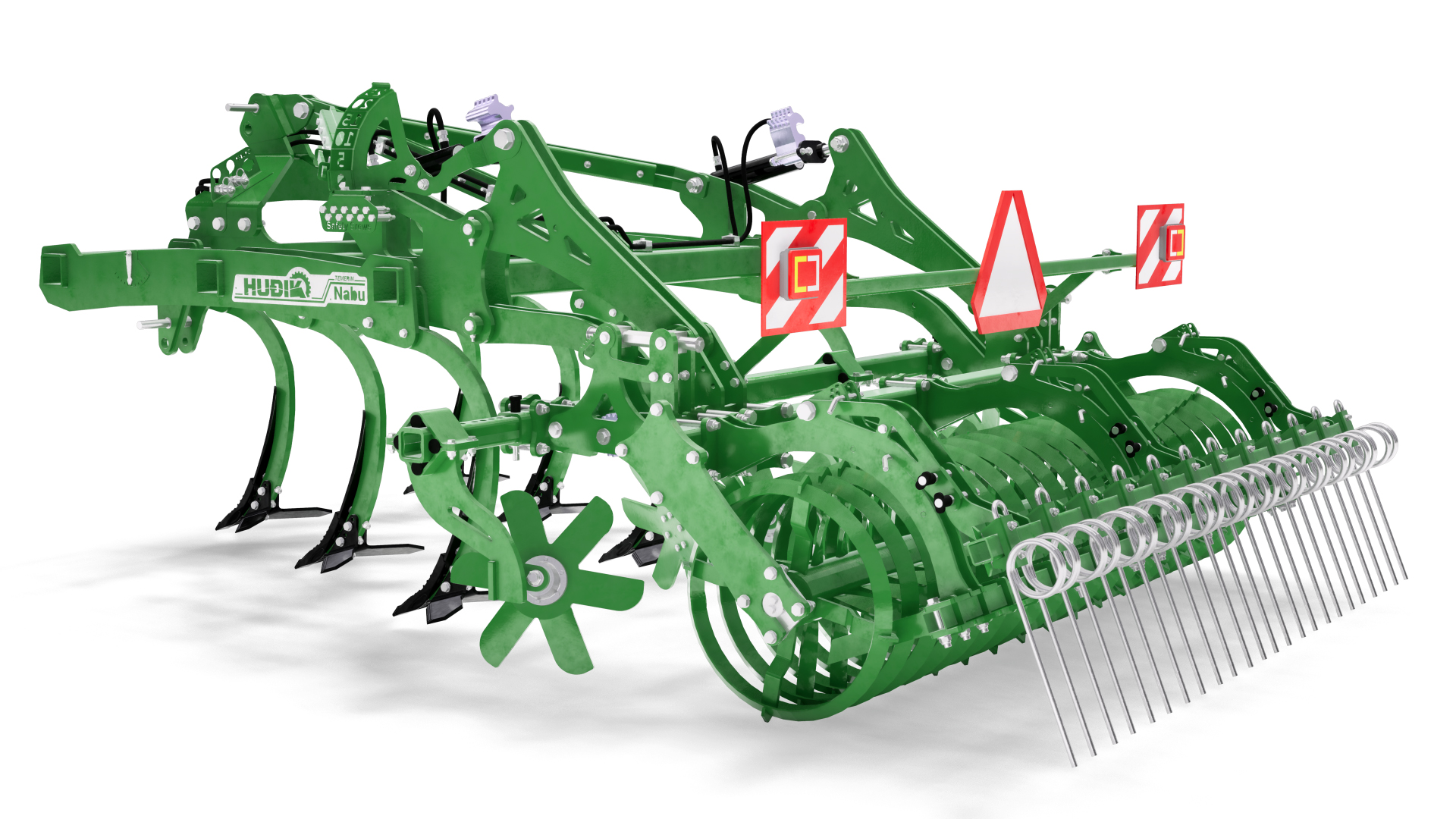

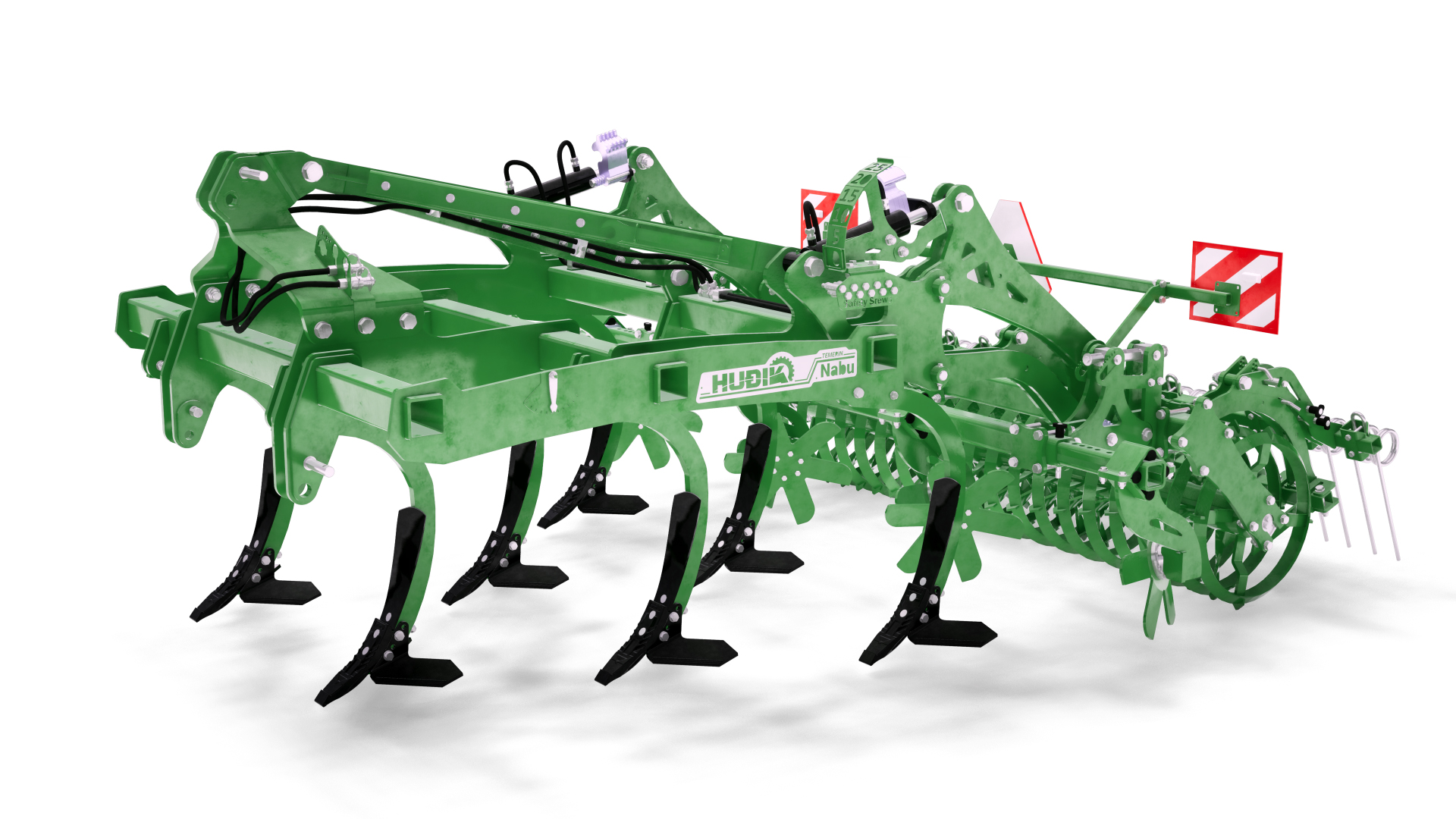

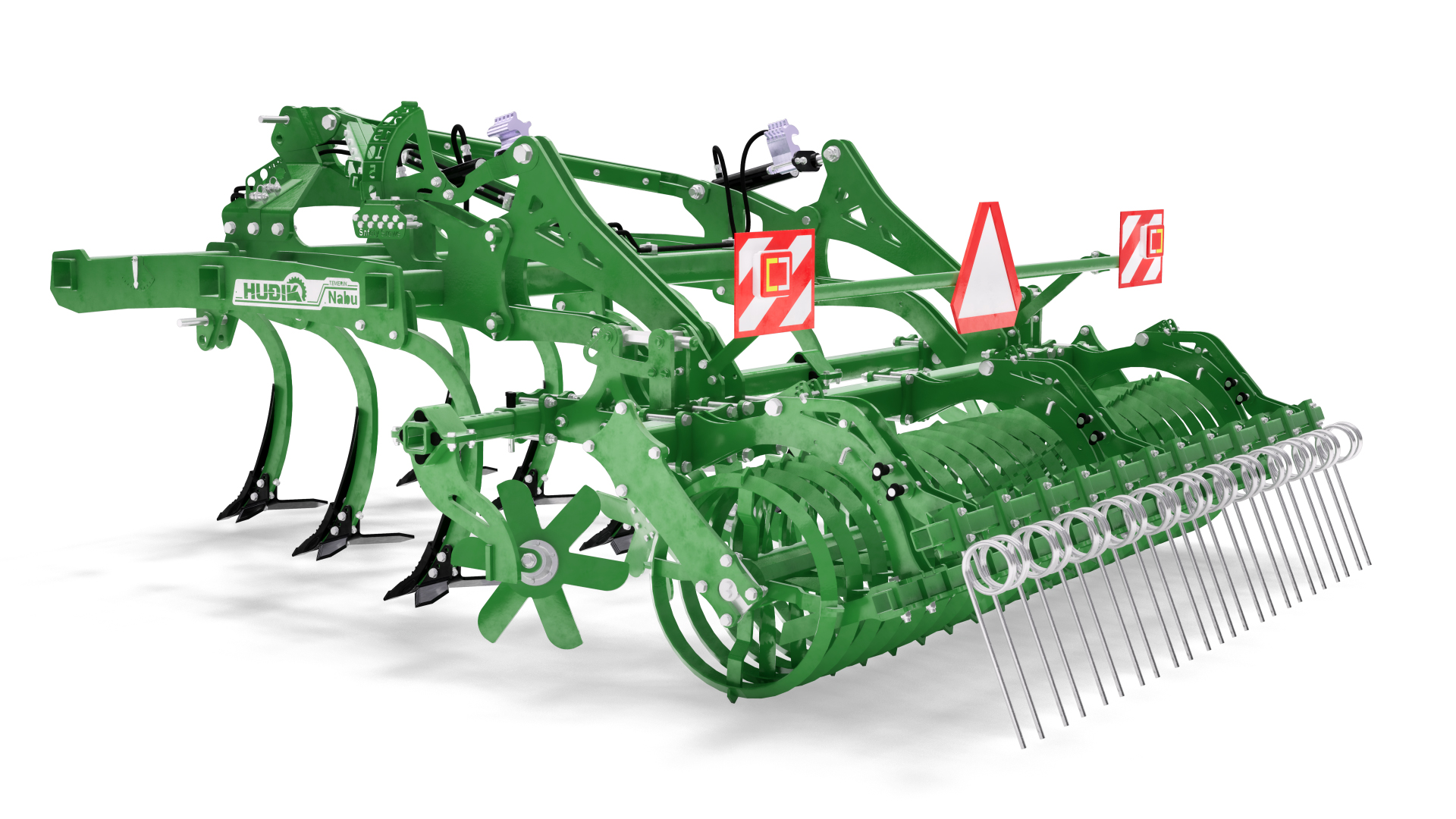

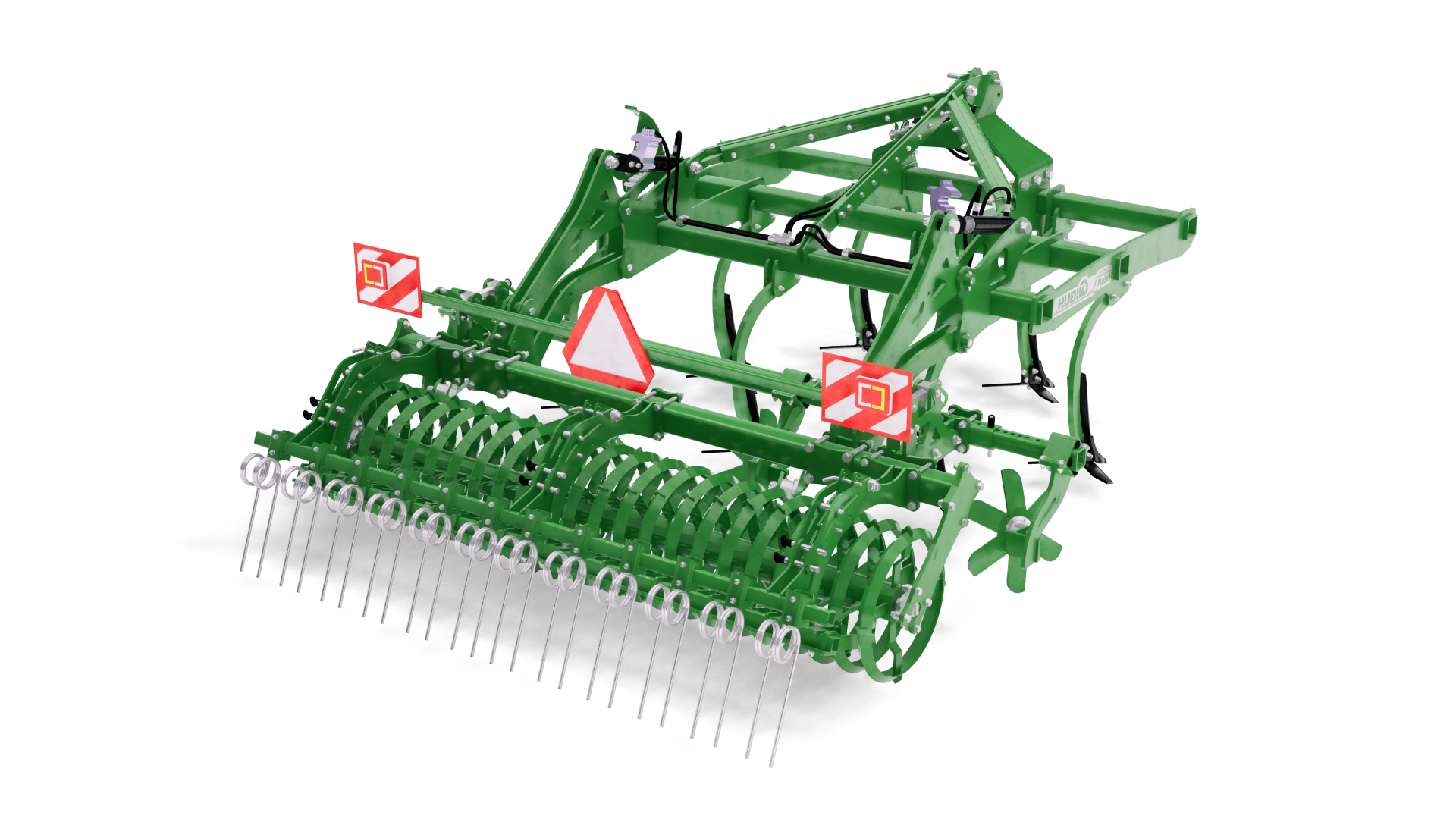

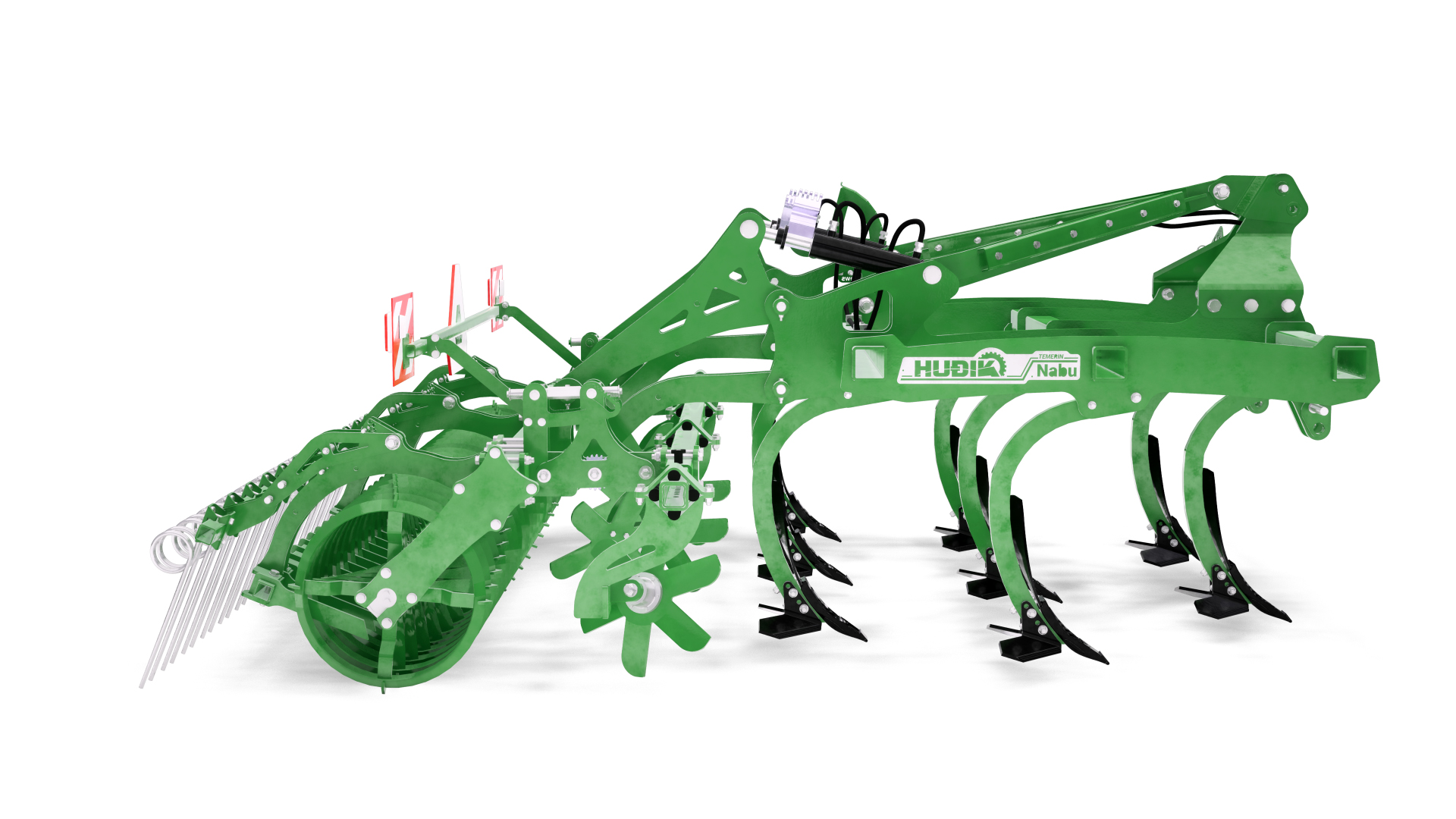

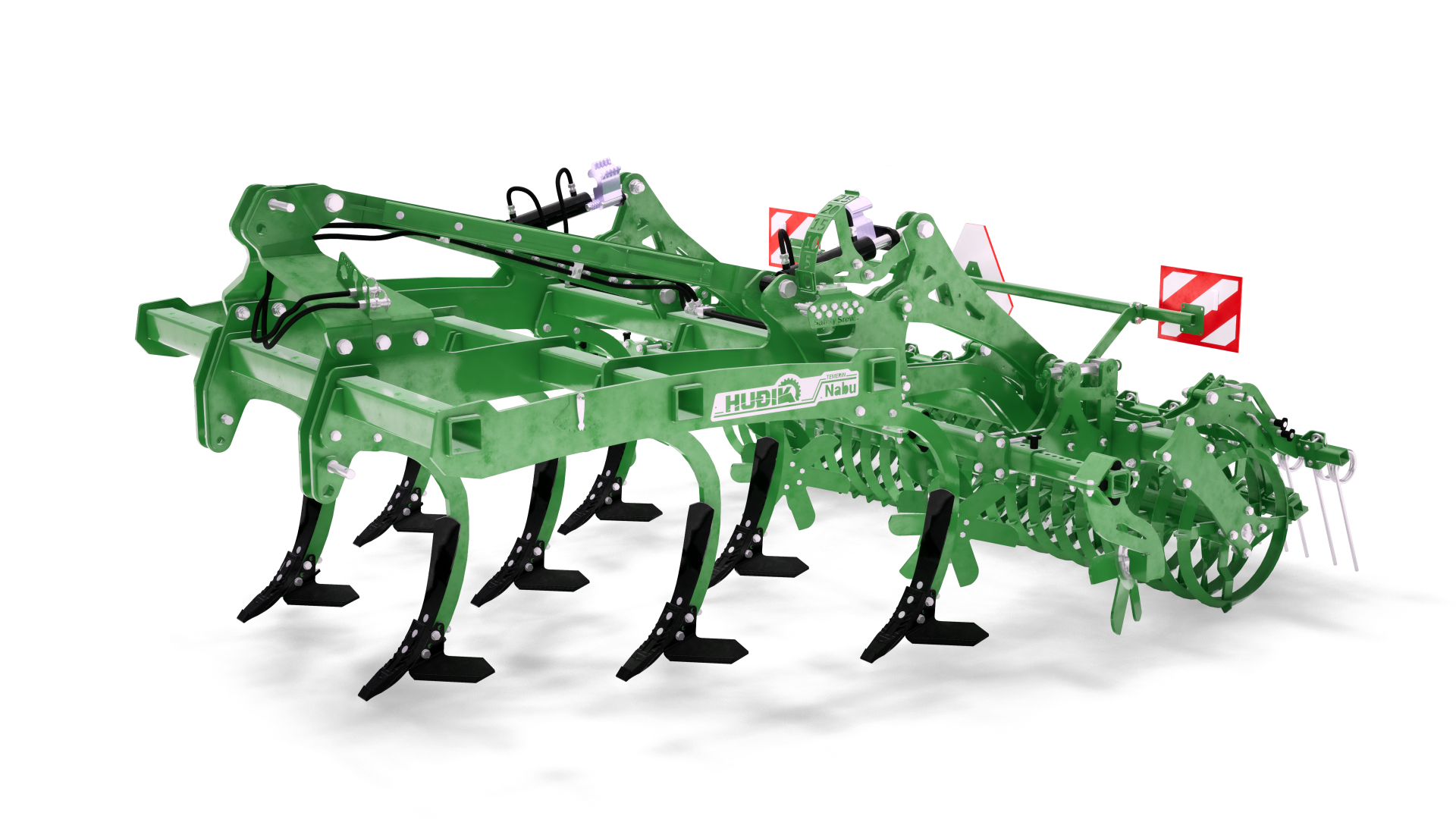

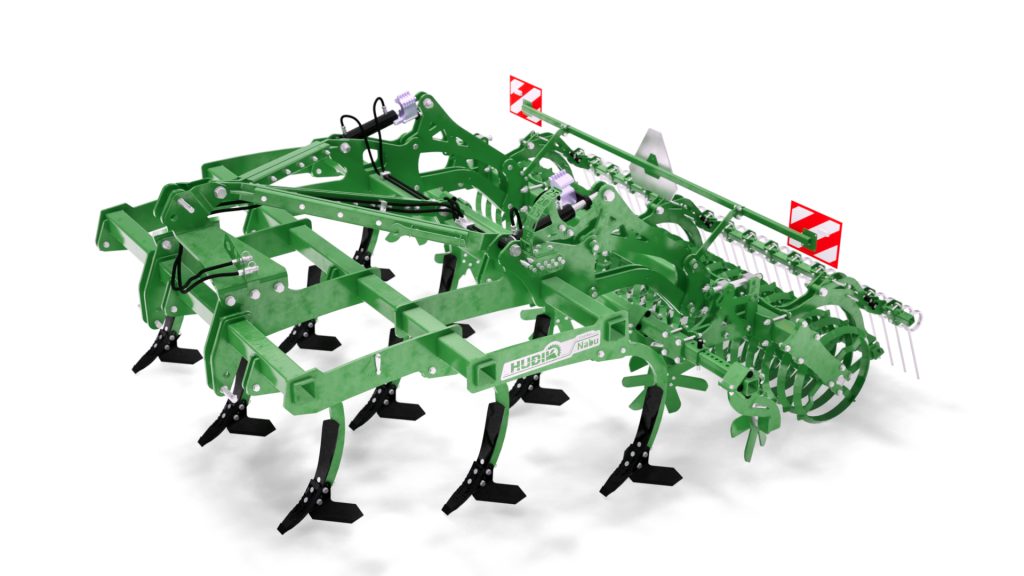

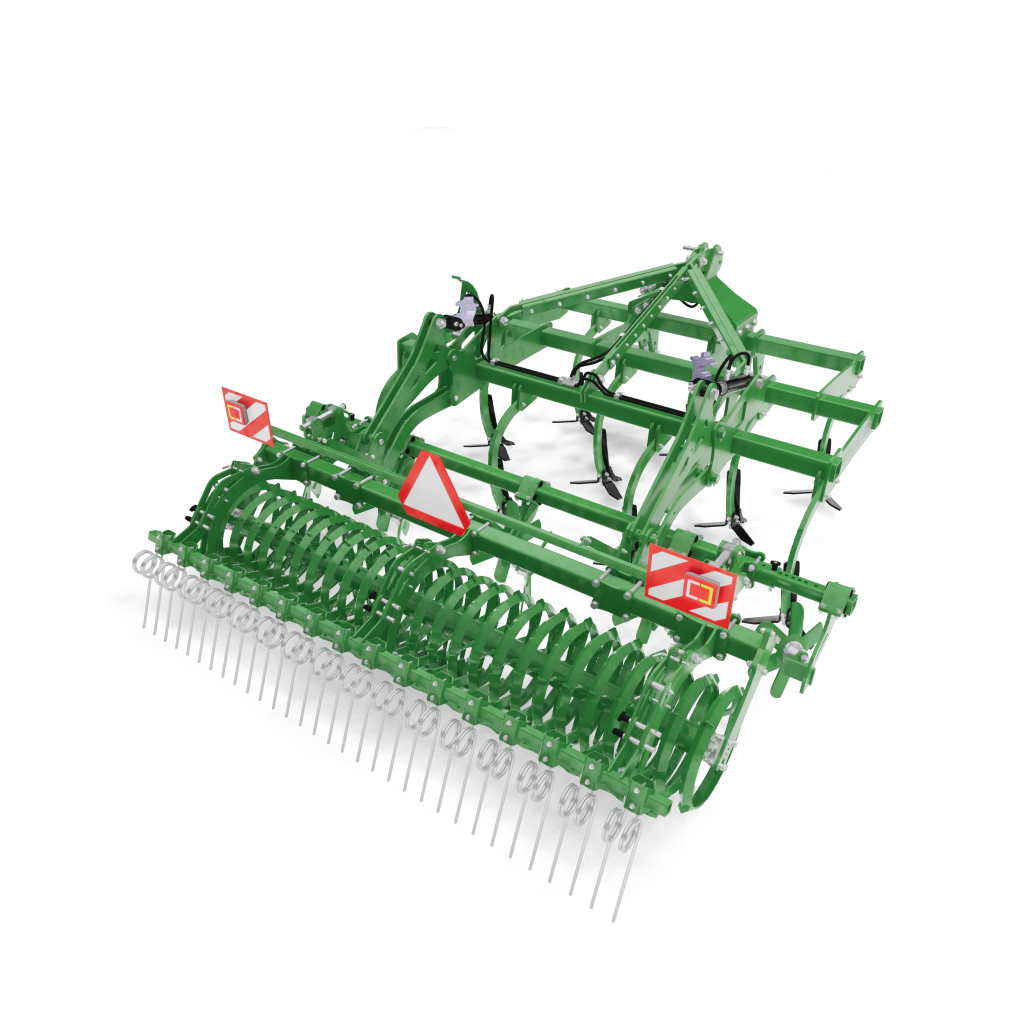

HUDJIK Gruber – the perfect tool for every task

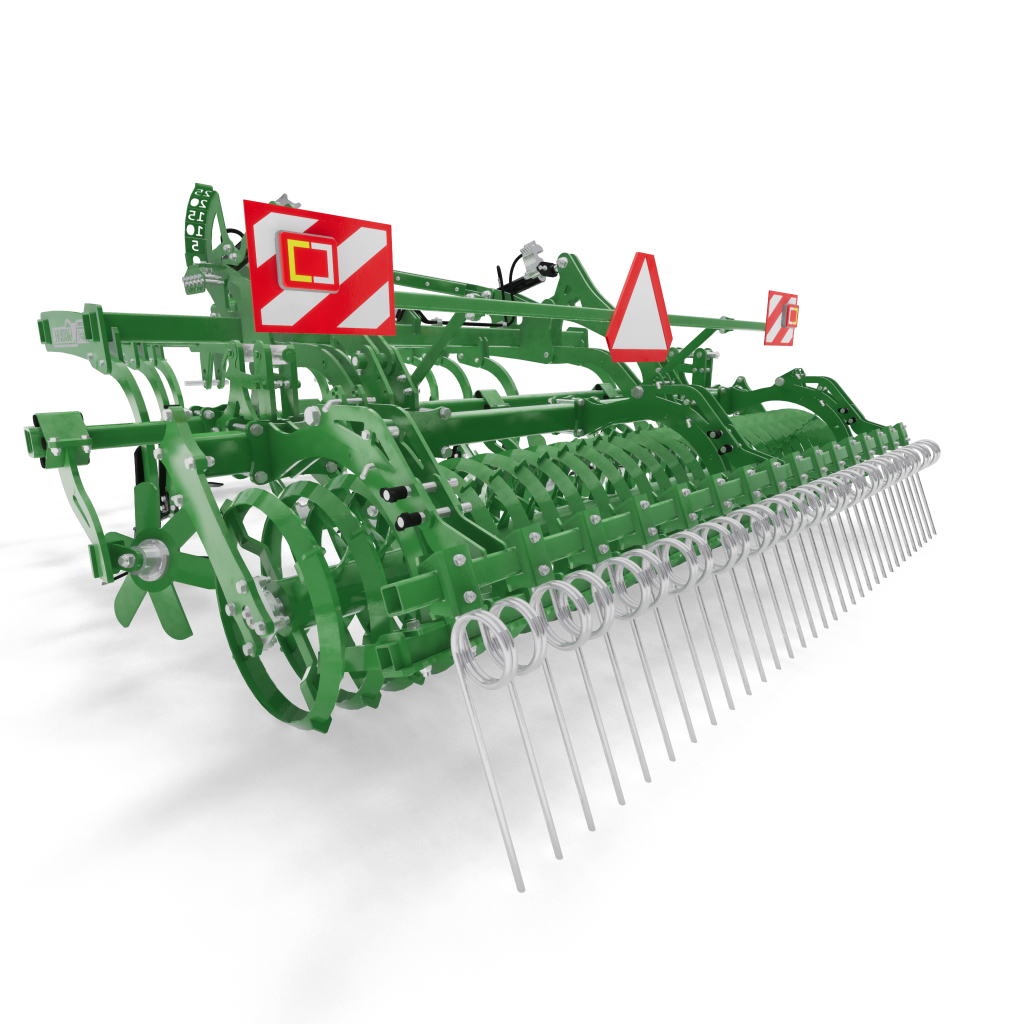

The HUDJIK grubber is designed for reduced tillage and uses a non-inversion method that replaces two traditional operations – ploughing and discing – in a single pass. It ensures perfect conditions for germination and healthy crop development while significantly reducing costs.

The 3-row HUDJIK grubber with wear wings fully meets the requirements of traditional soil cultivation. Its optimal design guarantees clog-free operation, excellent soil crumbling, and effective incorporation of crop residues into the soil, enhancing fertility, water retention, and erosion resistance.

Accurate working depth control with the HUDJIK grubber ensures that seeds are not sown too deep and emerge uniformly.

Medium-deep tillage facilitates faster decomposition of plant residues. In most areas, repeating medium-deep, intensive tillage is recommended after 2–3 weeks.

In case of large quantities of plant residue or unstable soil structure, deeper tillage (up to 15–25 cm) is needed. Deep loosening is also advisable in rainy harvesting conditions.

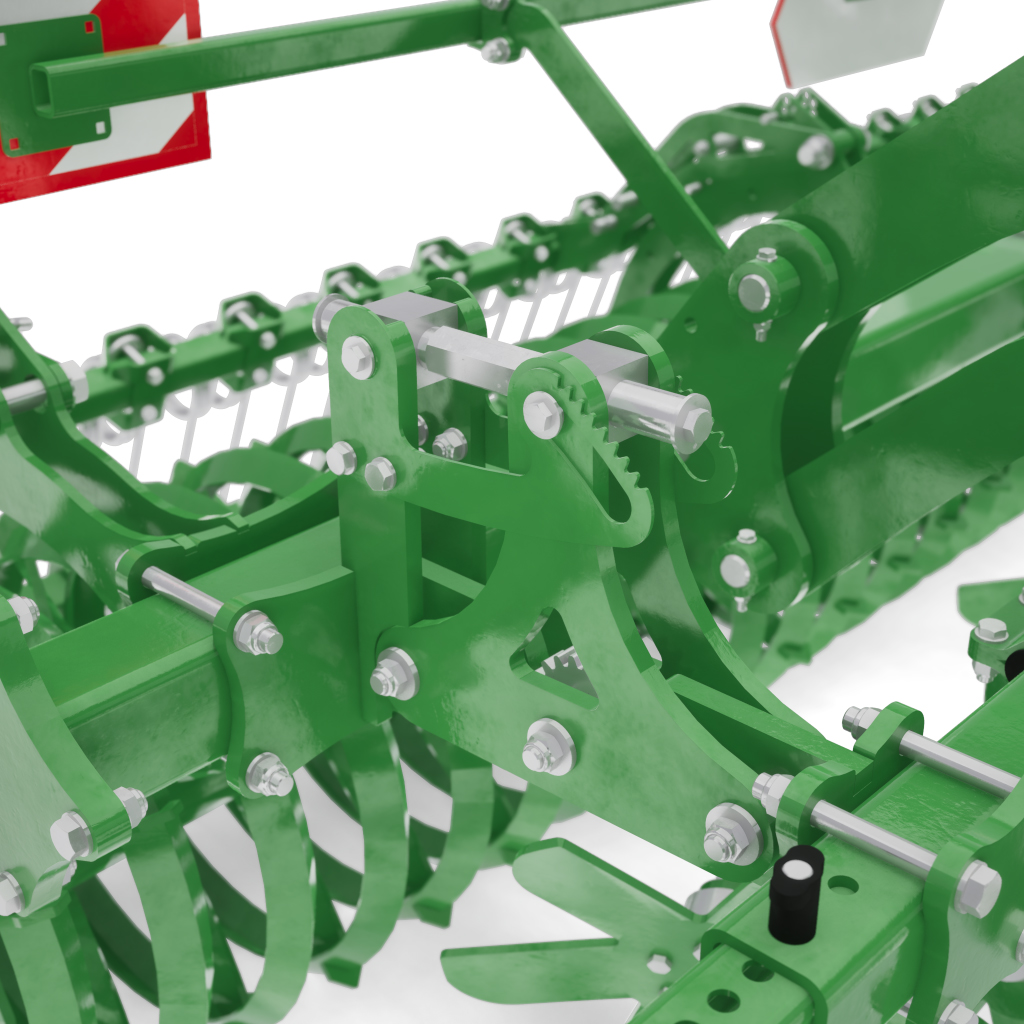

Working units

The working units are sourced from a renowned German manufacturer and made from high-quality steel. Their shape is optimized for top performance, excellent tillage quality, and long service life.

Frame

The machine frame is made of premium German steel, providing a very strong structure.

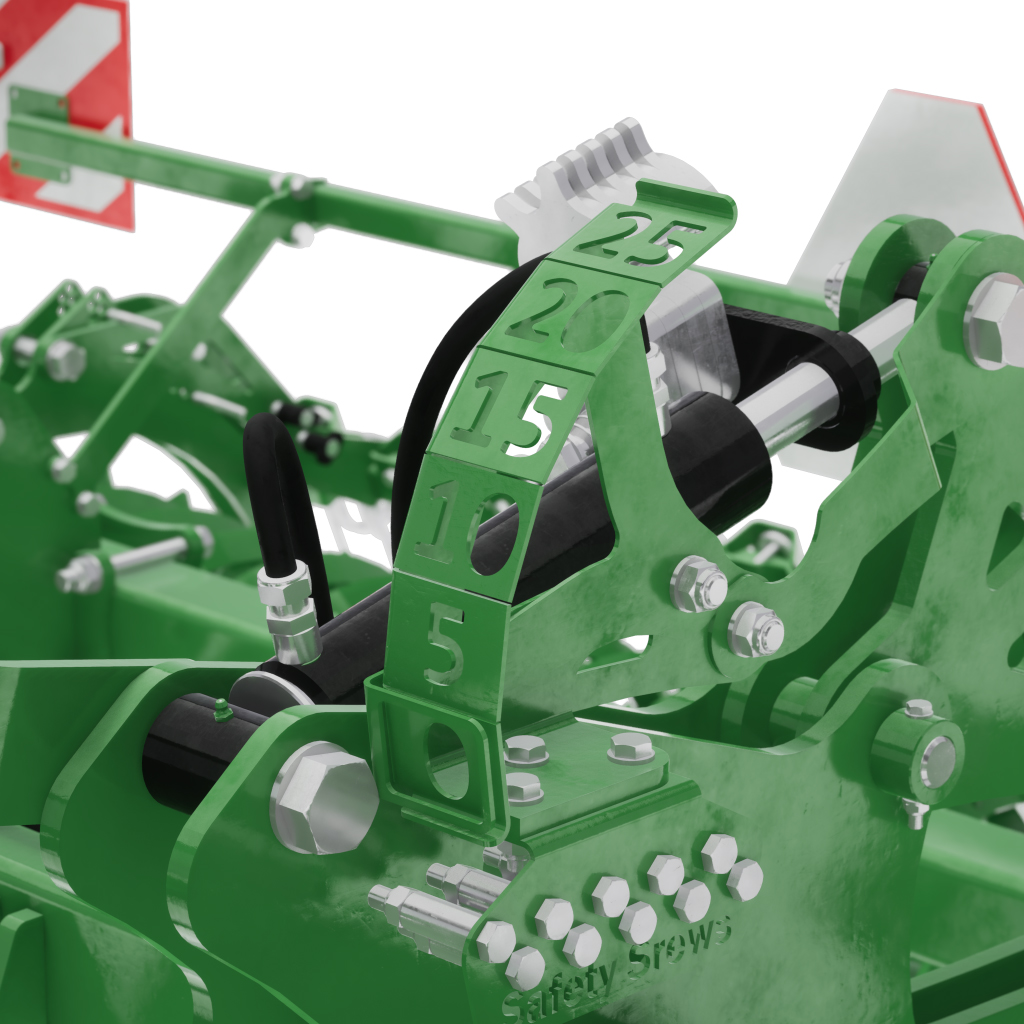

Working depth adjustment

The HUDJIK grubber has a user-friendly design. Working depth is hydraulically adjustable from the tractor cabin and is shown on a large display. Depth can be modified during operation without stopping the machine. The hydraulic depth control system includes a check valve (safety valve), protecting the tractor's hydraulic system even while working. Maximum working depth is 25 cm.

Disc adjustment

The disc working depth is also hydraulically adjustable from the tractor cabin and visible on a large display. Additionally, depth can be manually set using a spindle and gear mechanism.

The gear system maintains the parallel alignment of the discs in every positions.

Discs and hubs

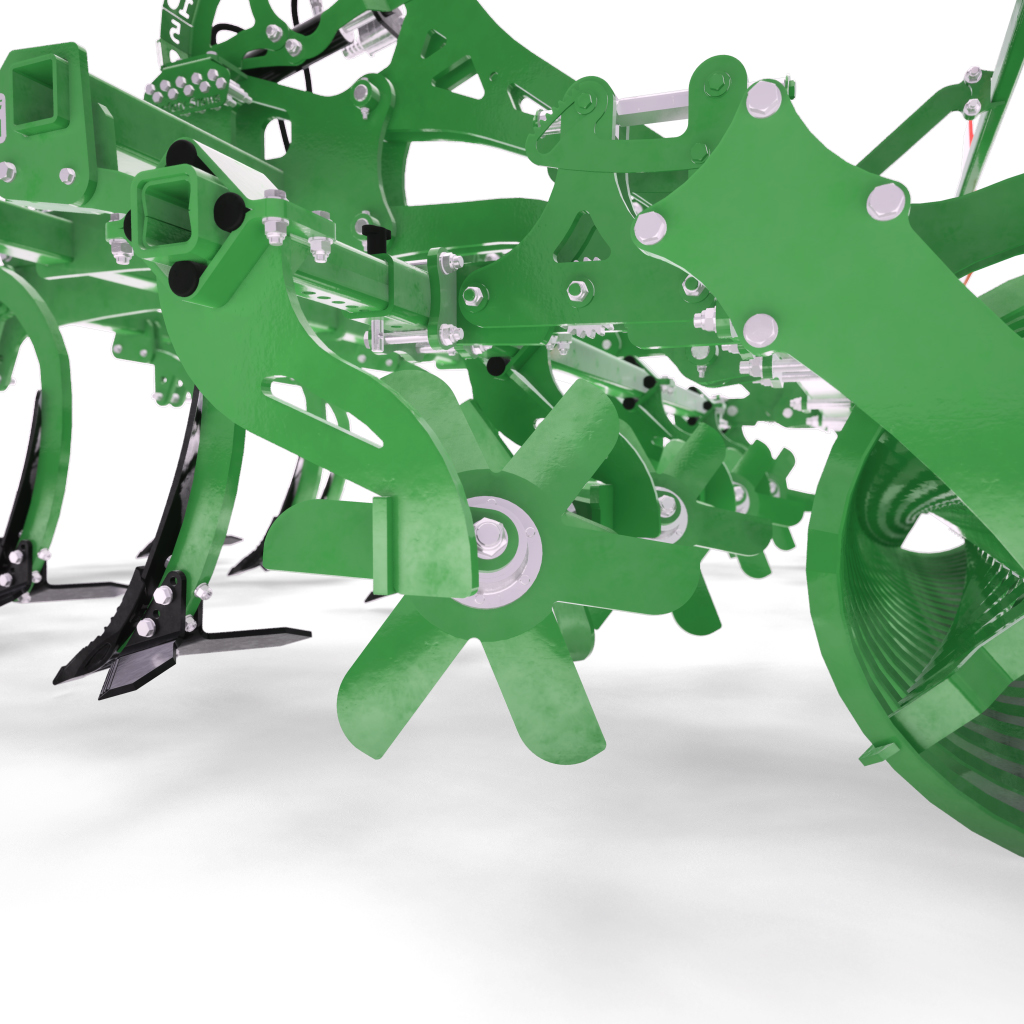

The discs are propeller-shaped, but flat discs are also available upon request. Propeller discs are made of boron-manganese steel without heat treatment and are later hardened to ensure reliability and durability. Their star shape not only distributes soil evenly but also crushes clods effectively. The wheel hubs are of premium quality. Bearings have cassette seals, are maintenance-free, and have a long service life.

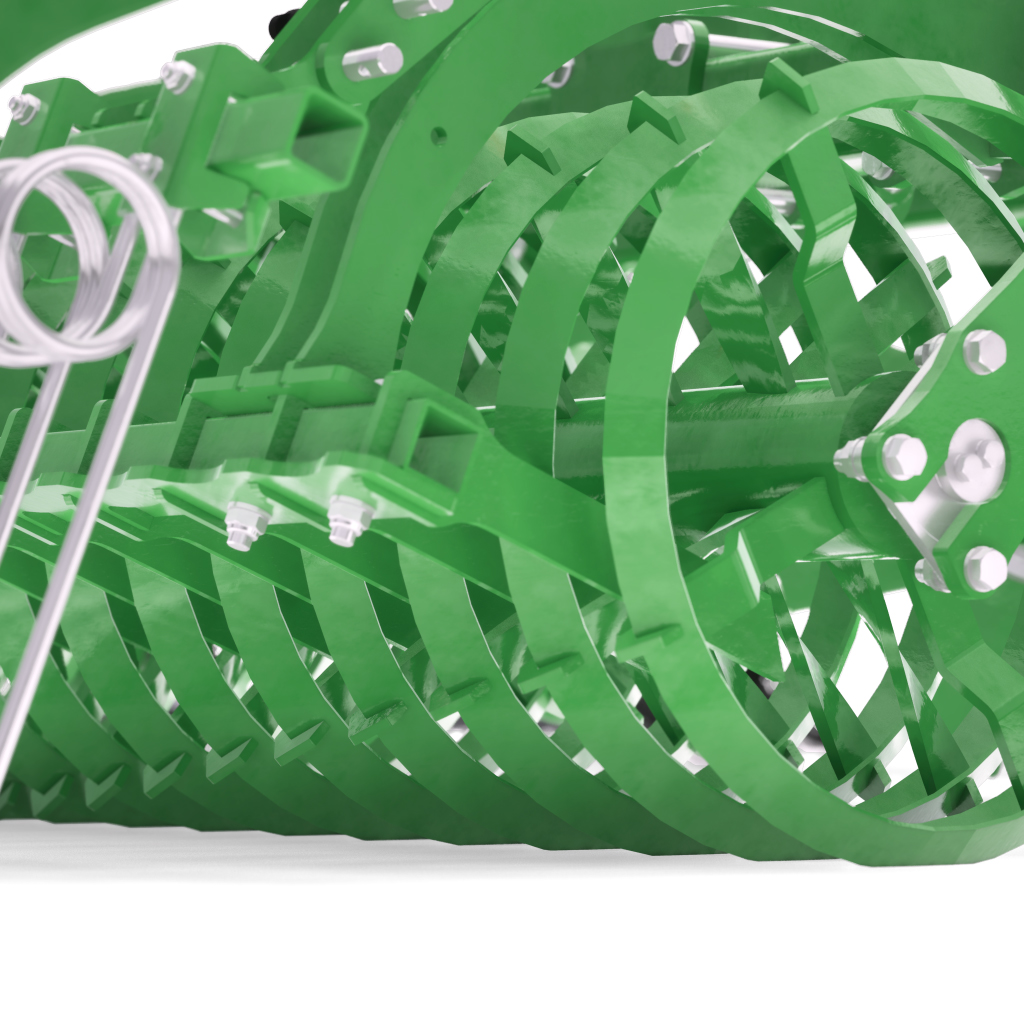

Roller

The roller has a 550 mm diameter and is made of 40x40 mm steel L-profiles ("Steel Press"). Its edges are serrated to prevent slippage and it's equipped with scrapers.

Scraper replacement

Scrapers are easy to replace without cutting, welding, or replacing the entire holder.

Surface protection

The machine is powder-coated using a modern plasticizing method with top-quality powder paints from renowned German manufacturers.

Advantages of HUDJIK Gruber:

| HUDJIK GRUBER | NABU 2.15 | NABU 2.5 | NABU 3.0 | NABU 4.0 |

|---|---|---|---|---|

| Working width [m] | 2.15 | 2.5 | 3.0 | 4.0 |

| Transport width [m] | 2.15 | 2.5 | 3.0 | / |

| Transport height [m] | 2.15 | 2.5 | 3.0 | / |

| Length [m] | 3.35 | 3.35 | 3.35 | 3.35 |

| Weight with SteelCut roller [kg] | 1255 | 1385 | 1555 | / |

| Pneumatic cylinder dimensions | / | / | / | / |

| Number of working units | 7 | 8 | 10 | 13 |

| Spacing of working units in line [cm] | 90 | 90 | 90 | / |

| Spacing of tine legs in line [cm] | 30 | 30 | 30 | / |

| Frame height [cm] | 85 | 85 | 85 | 85 |

| Required tractor power [HP] | 100-120 | 150-170 | 180-200 | 240-260 |

| Distance between tines [cm] | 37 | 37 | 37 | 37 |

| Light-signaling | Standard | Standard | Standard | Standard |

| Hydraulic depth adjustment | Optional | Optional | Optional | Optional |

Galery