Agricultural machines

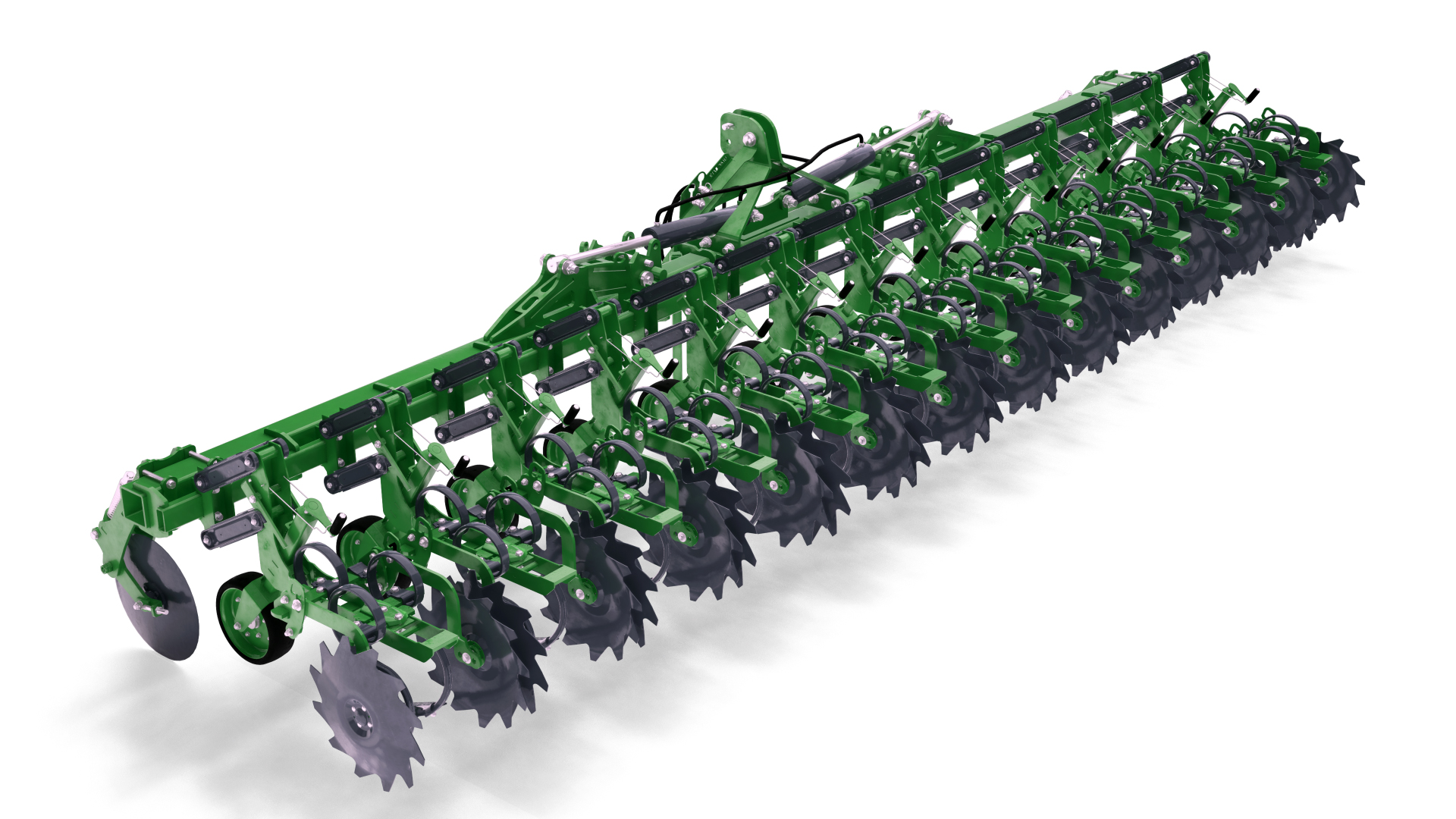

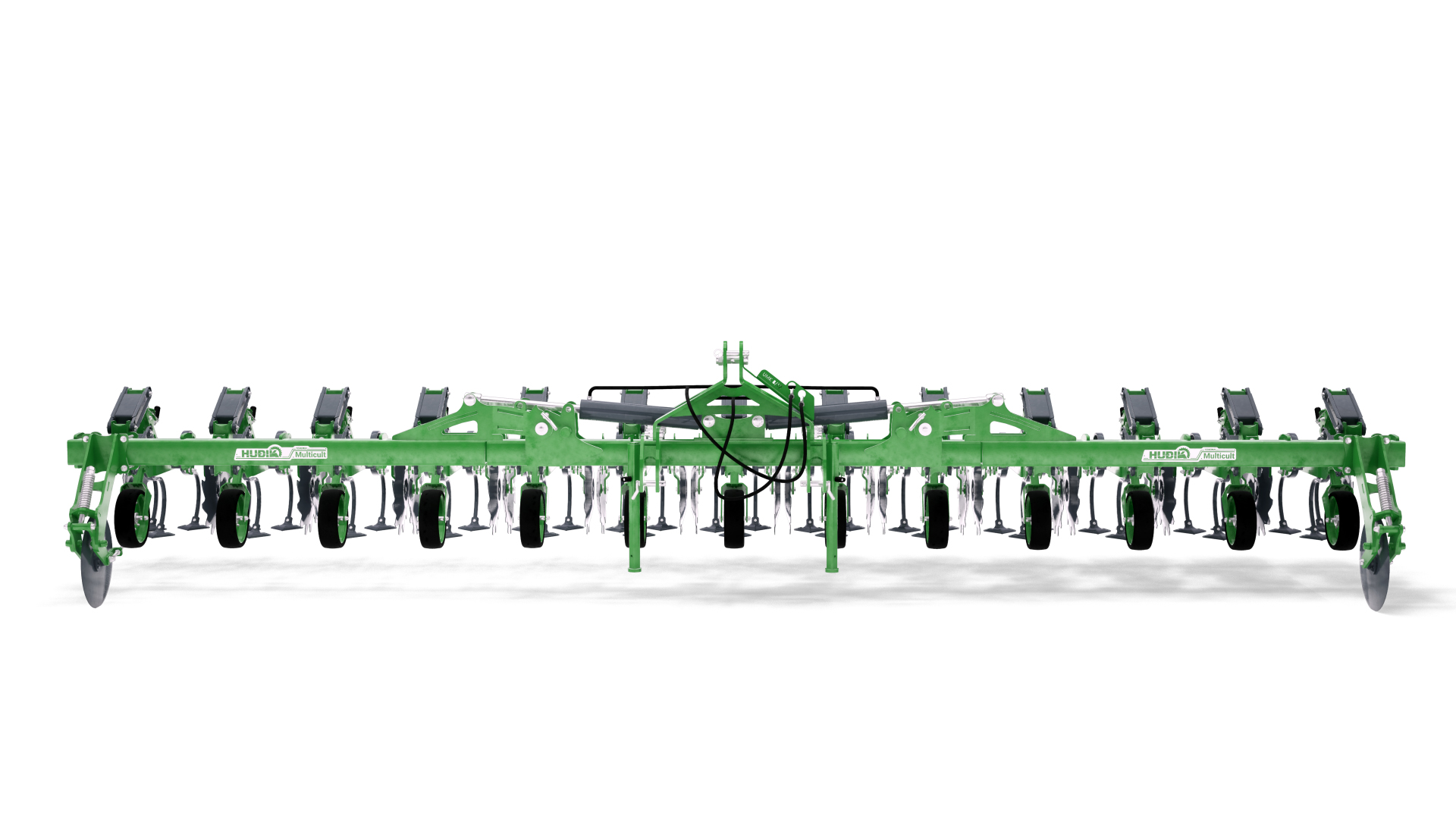

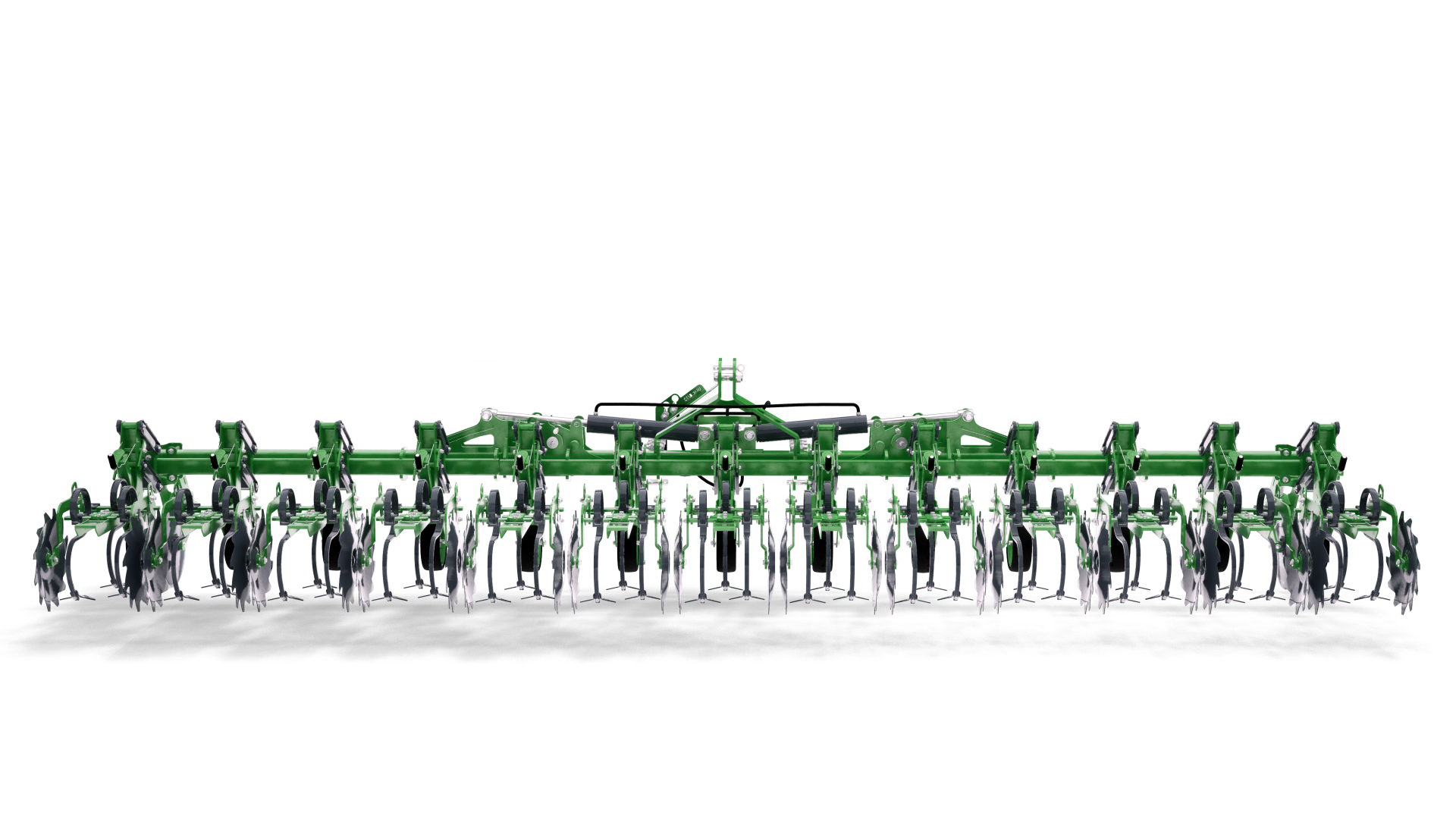

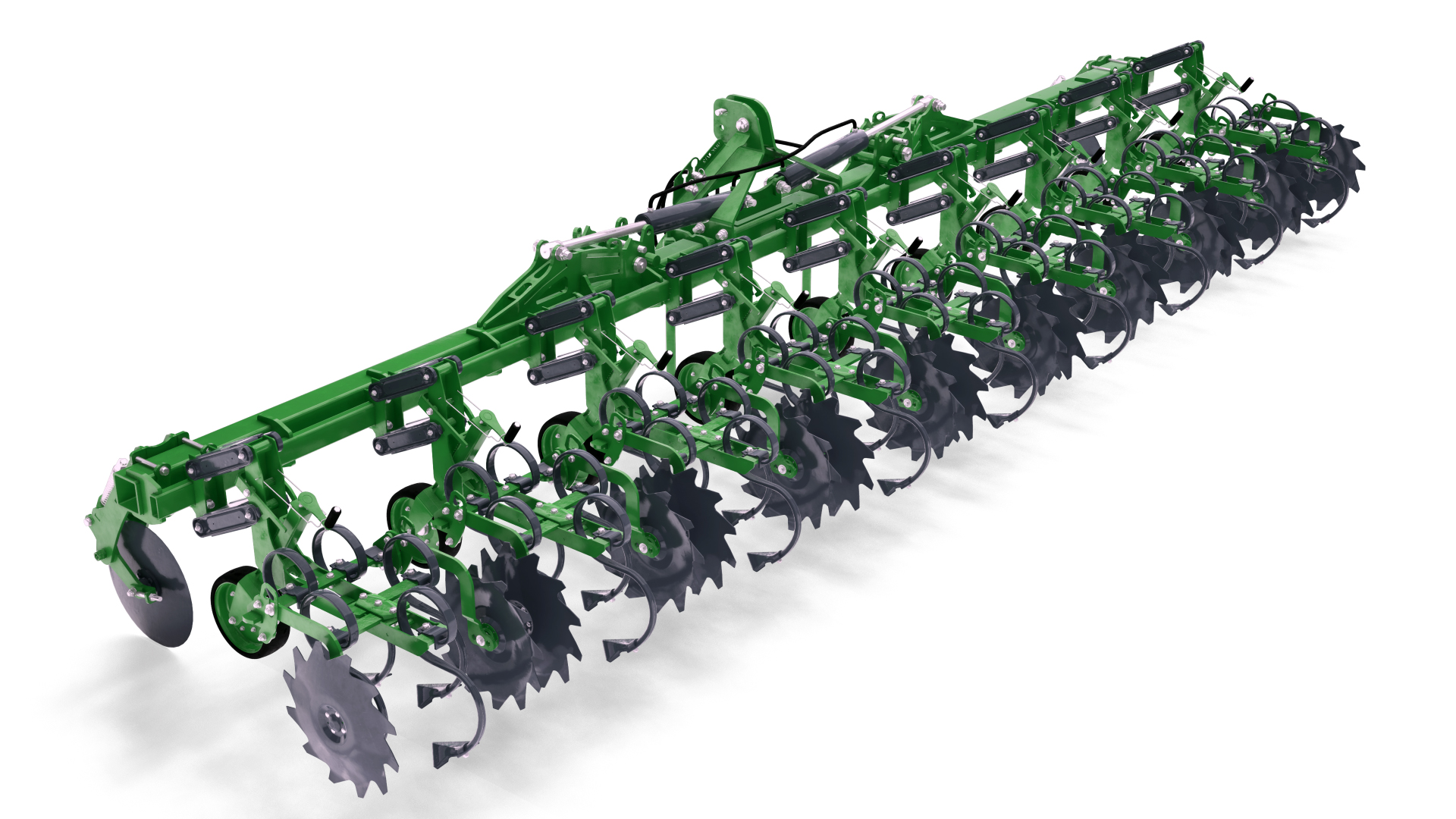

Cultivator

Traditional soil cultivation methods like inter-row cultivation (also known as hoeing) have been unjustly pushed into the background due to the increased use of herbicides in recent years. However, thanks to the rise of organic farming and the growing emphasis on environmental protection, it is regaining its rightful place—not only because of its positive effects on crops and the environment, but also due to its significant economic benefits and cost-saving potential.

Below are several advantages that contribute to healthy plant development, increased yields, and reduced production costs:

This universal machine can be used for inter-row cultivation of wide-row crops such as maize, sugar beet, sunflower, soybean, rapeseed, legumes, sorghum, and various vegetables.

Simplicity

HUDJIK machines are extremely simple and robust in design. With proper handling, careful maintenance, and regular lubrication, they ensure a long service life, which is supported by real-world use. Maintenance requirements are minimal, usually limited to replacing wear parts.

Precision

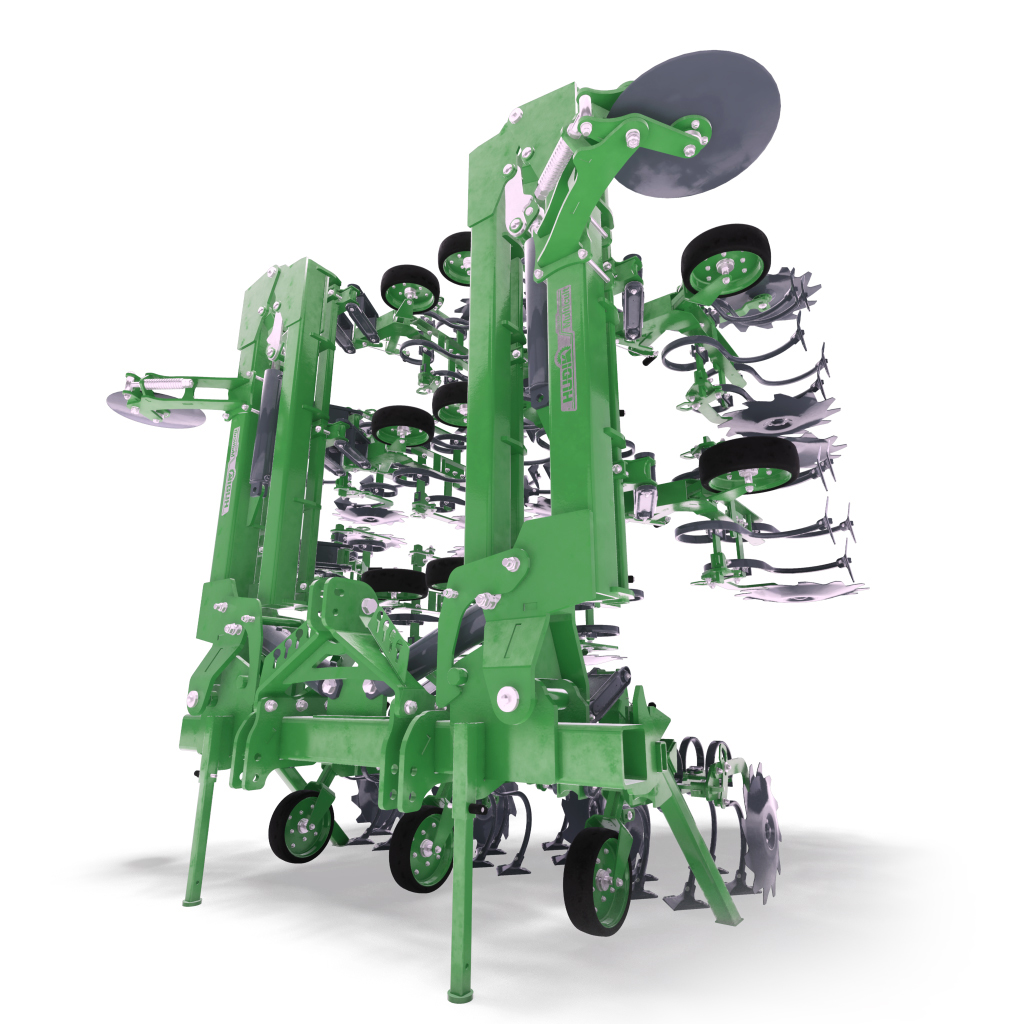

The precise guide discs make steering easier and ensure that the inter-row cultivator moves correctly even on uneven terrain or when the tractor is swerving. They allow for perfect row tracking regardless of weed height, without the need for an expensive camera-guided system.

Perfect weed removal accuracy

When combined with large, serrated protective discs that prevent plant burial and damage to roots or stems, weeding can be performed at an early stage of development without harming the plants.

Working height

A working height of up to 65 cm allows the machine to be used even when the plants are in a more advanced growth stage.

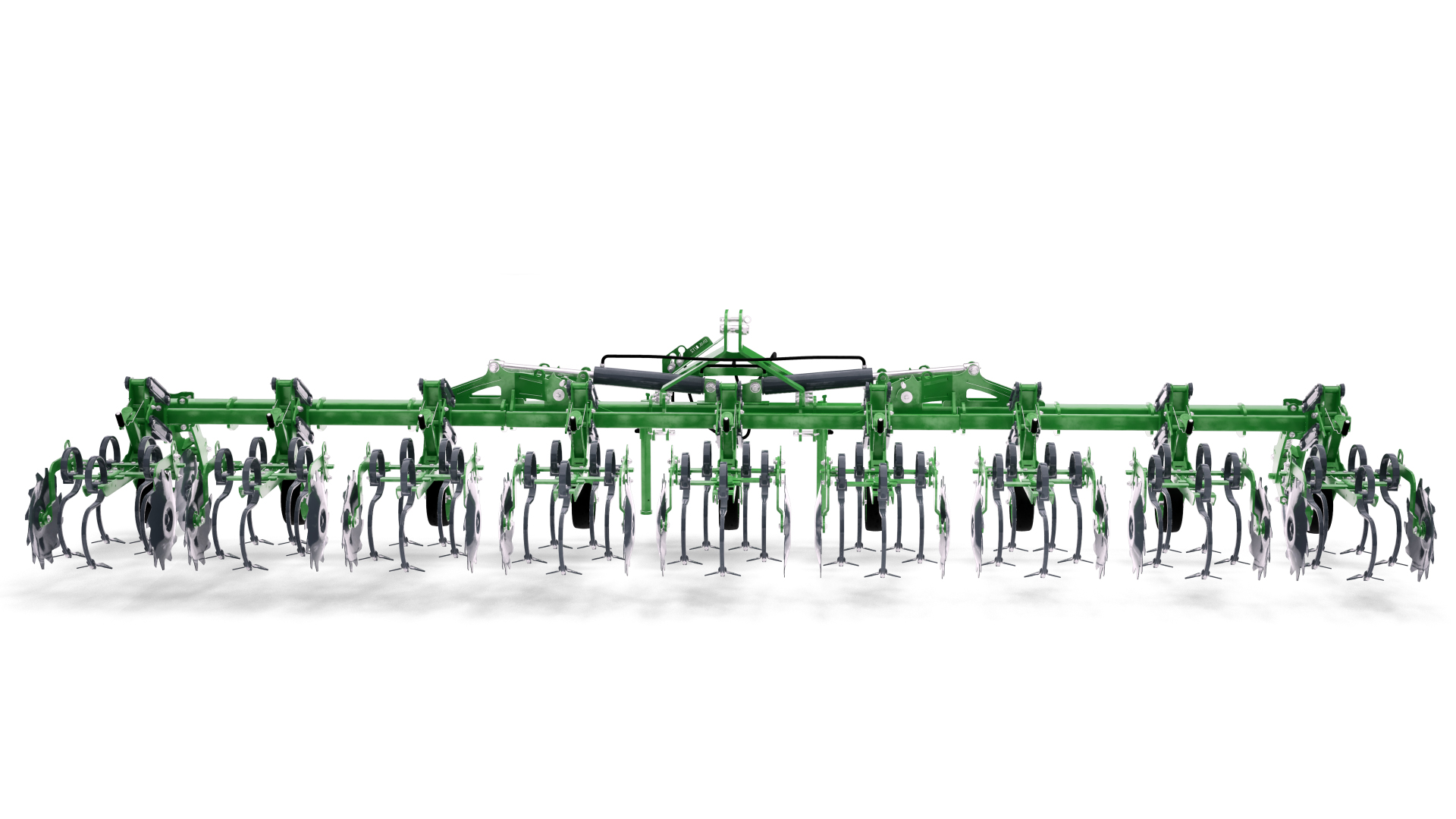

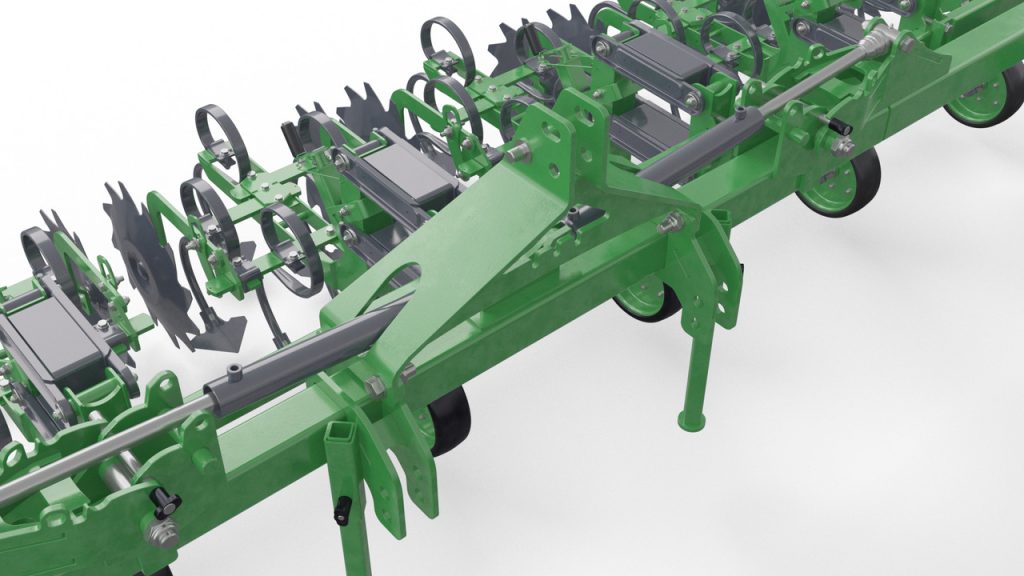

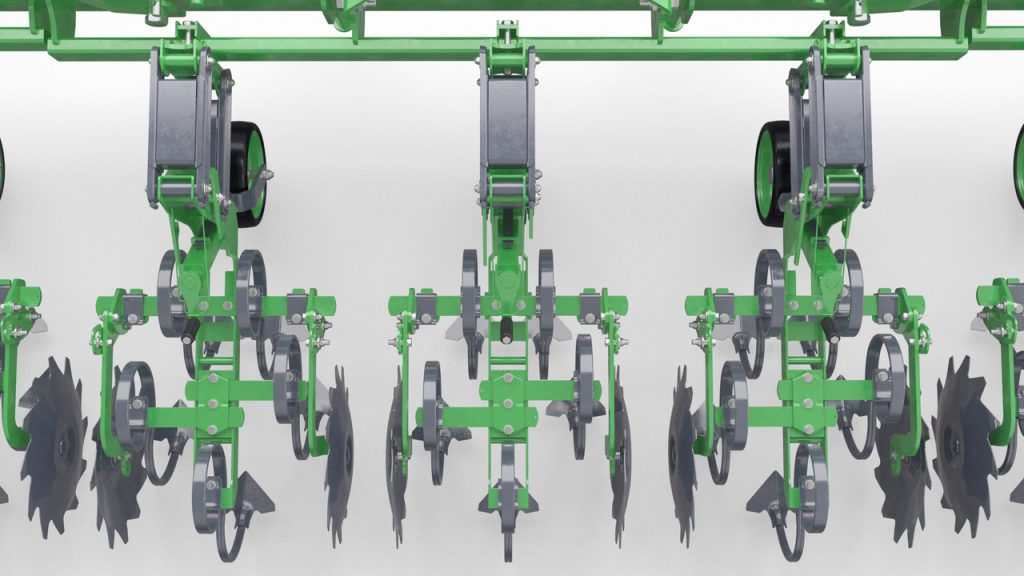

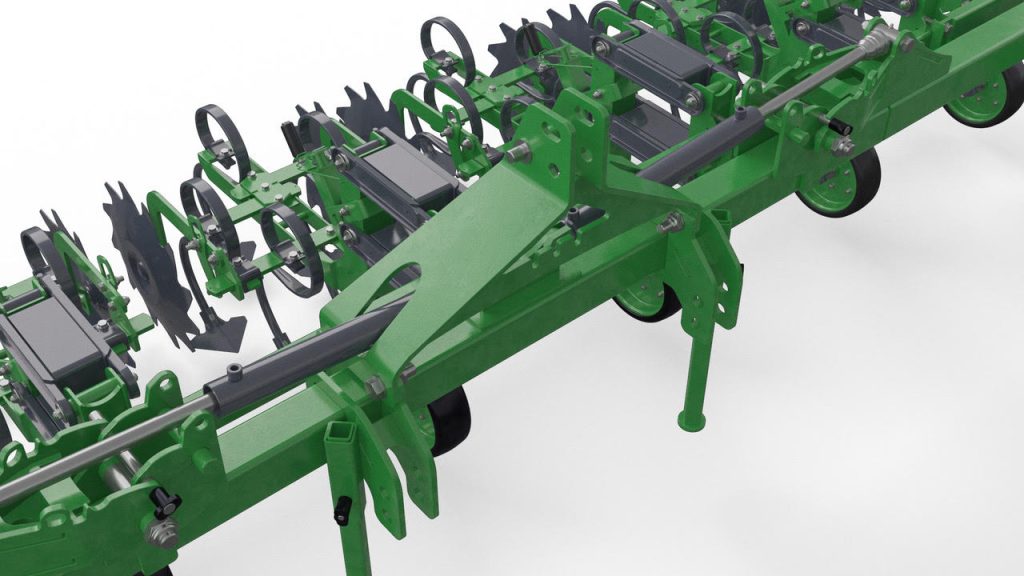

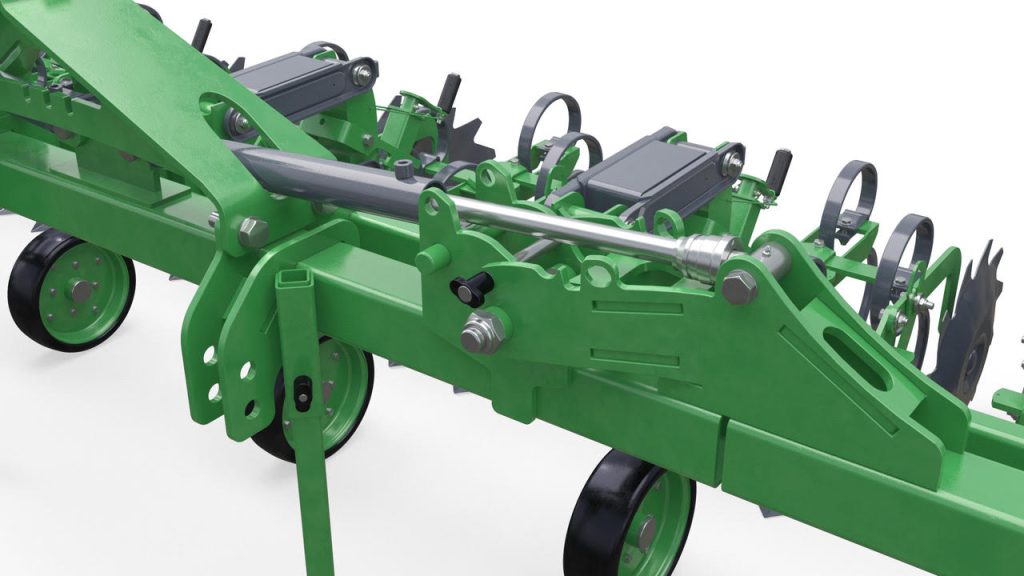

Cultivator equipped with S-Tines

The HUDJIK inter-row cultivator, equipped with S-tines and protective discs, enables high-speed cultivation between rows. It cuts weeds at the roots and lifts them from the soil, where they quickly dry out. At the same time, the soil structure is not damaged but rather loosened and aerated. The optimal working speed is 10–12 km/h. The design allows accurate row tracking even on uneven ground. Each working unit (row body) operates independently, with its own depth and parallel guide wheel, ensuring the hoe always works at the required depth. Wheel bearings, discs, and oscillating mechanisms are sealed and permanently greased, requiring no additional lubrication—reducing maintenance costs and simplifying use.

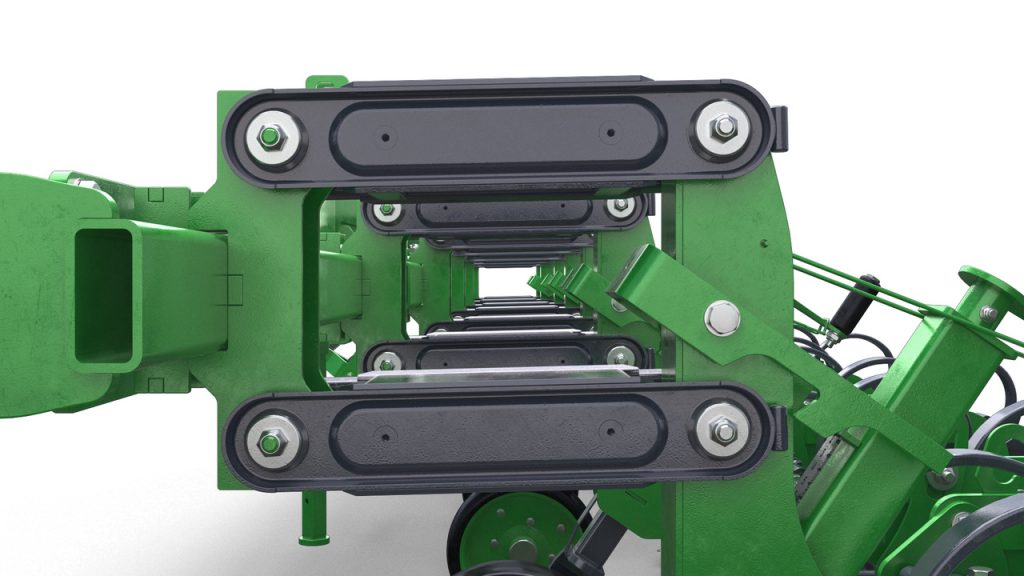

Construction with oscillatory mechanism

A unique feature of HUDJIK inter-row cultivators is the specially designed oscillating mechanism with tapered roller bearings, ensuring precise operation, easy adjustment, and long service life—eliminating the need for major refurbishments due to wear.

Distance between hoes

For row spacing up to 55 cm, each unit uses 3 hoes; for wider spacing, 5 hoes are mounted on a parallelogram. The universal inter-row cultivator can be attached to a tractor in three different ways, depending on the tractor type and hitch category, allowing optimal configuration.

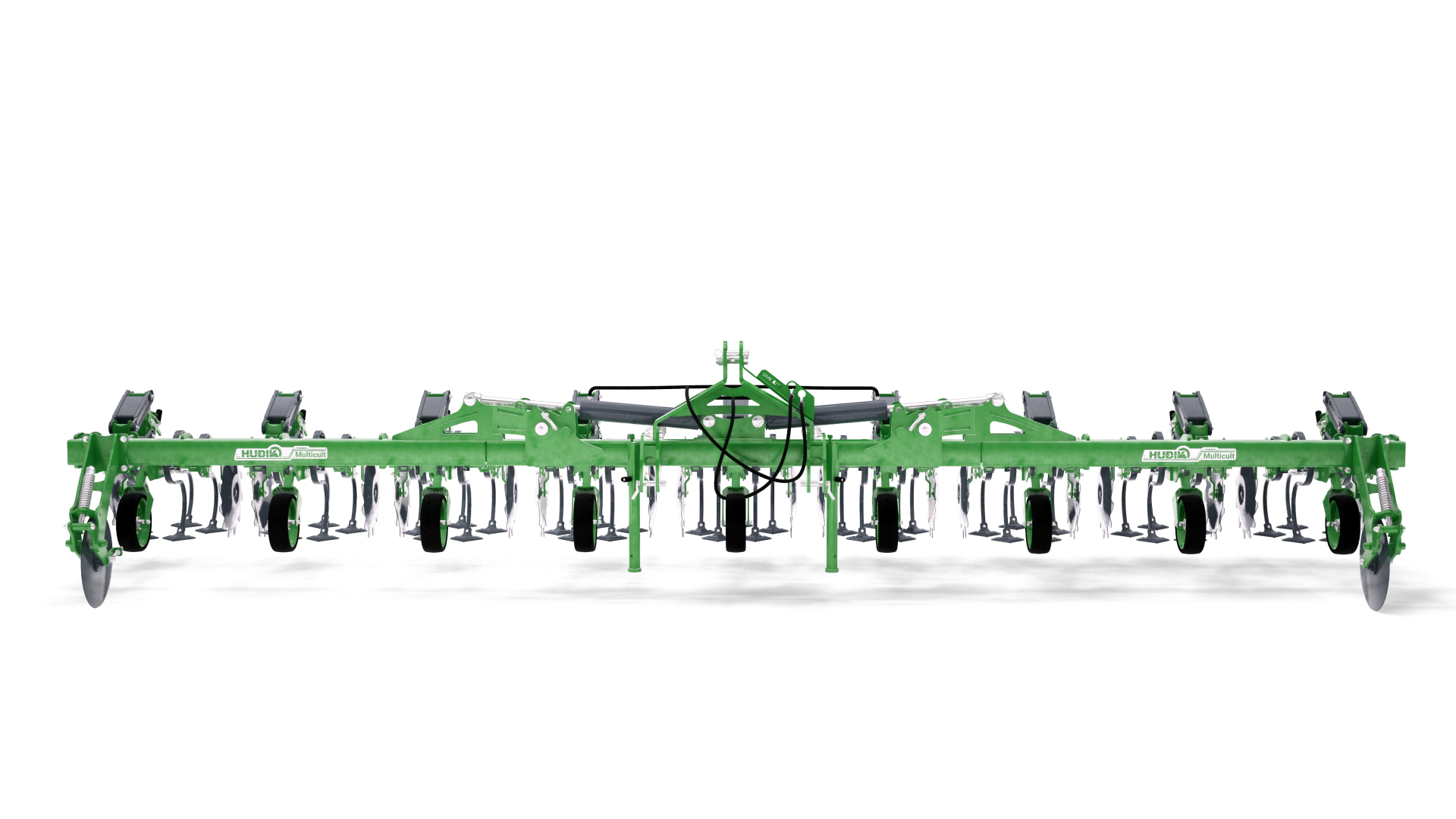

Hydraulically foldable inter-row cultivator

For working widths over 3 meters, HUDJIK company also offers cultivators with a special foldable frame. Folding is performed by a hydraulic cylinder, which can be controlled directly from the tractor cab.

Catalogue parts

| Characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Types/subtypes of universal inter-row cultivator UMK | ||||||||||

| Beams | UMK-4 | UMK-6 | UMK-12 | UMK-18 | ||||||

| UMK-4K | UMK-6R | UMK-6K | UMK-7R | UMK-8R | UMK-8K | UMK-12R | UMK-12K | UMK-18R | ||

| Number of rows | 4 | 6 | 6 | 7 | 8 | 8 | 12 | 12 | 18 | |

| Minimum recommended tractor power (kW/HP) | 30/40 | 40/55 | 40/55 | 40/55 | 40/55 | 50/70 | 70/95 | 88-120 | 88-120 | |

| Maximum working width (cm) | 337 | 337 | 497 | 497 | 497 | 637 | 637 | 920 | 920 | |

| Approximate transport dimensions HxL (m) | 1.55x2.7 | 1.55x2.7 | 2.33x2.7 | 2.33x2.7 | 2.33x2.7 | 2.95x3.1 | 2.95x3.1 | 2.95x2.95 | 2.95x2.95 | |

| Approximate weight (kg) | 700 | 820 | 850 | 890 | 930 | 1020 | 1300 | - | - | |

|

Wing folding method: mechanical (M) or hydraulic (H) and number of hydraulic cylinders (pcs.) | M - | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 4 pcs | H 4 pcs | |

| Leading discs | - | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Number of rubber-wheeled middle sections (pcs.) | 1 | 5 | 3 | 4 | 5 | 3 | 5 | 3 | 5 | |

| Number of metal-wheeled middle sections wheel (pcs.) | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Number of sections on the left beam (pcs.) | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 5 | 7 | |

| Number of sections on the right beam (pcs.) | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 5 | 7 | |

| Number of spring tines (pcs) | 31 | 19 | 31 | 22 | 25 | 41 | 37 | 61 | 55 | |

| Row spacing (cm) | 65-70-75-76.2 | 45-50 | 65-70-75-76.2 | 45-50 | 45-50 | 65-70-75-76.2 | 45-50 | 65-70-75-76.2 | 45-50 | |

| Working speed (km/h) | 7-14 | |||||||||

Galery