Agricultural machines

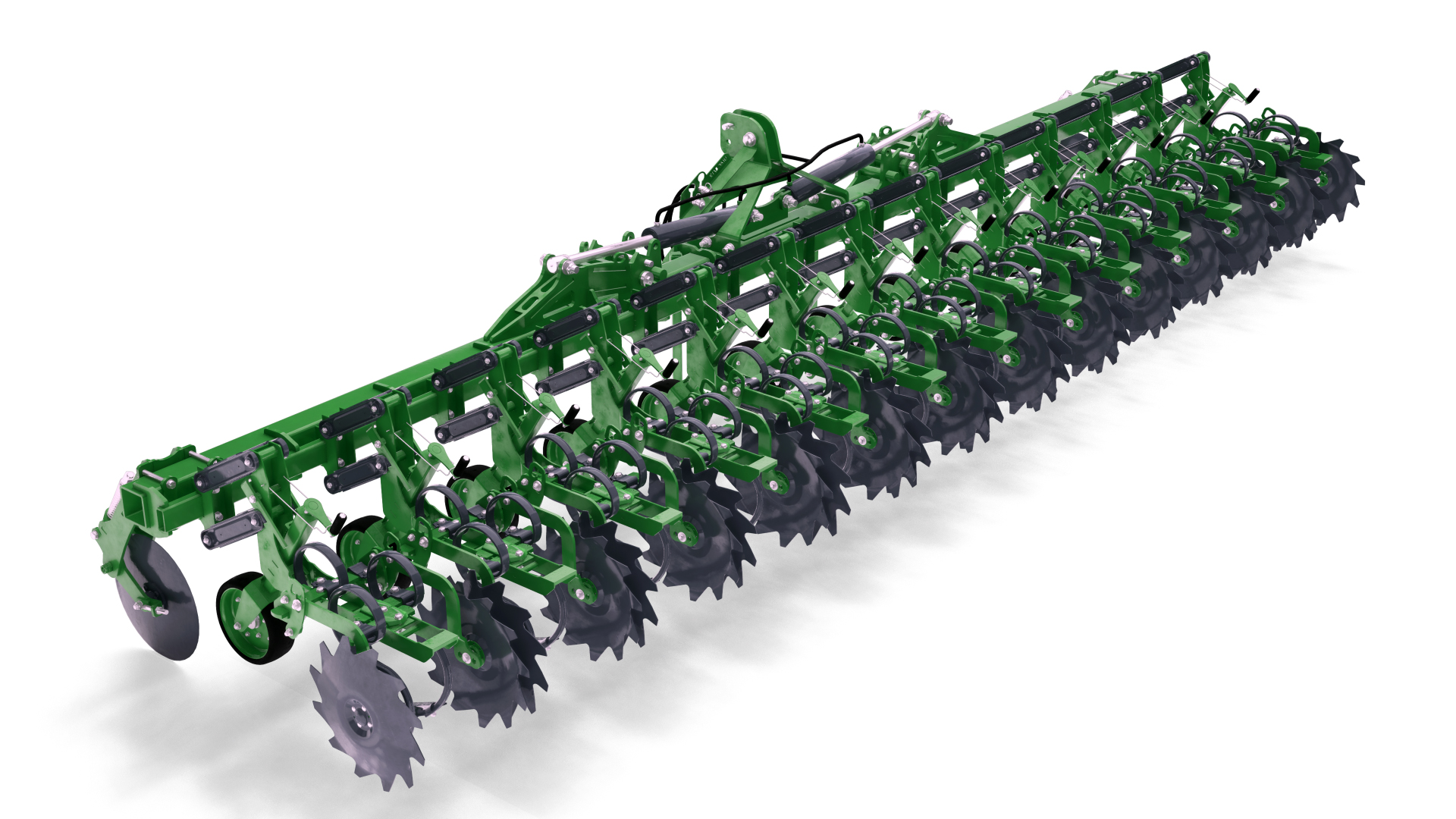

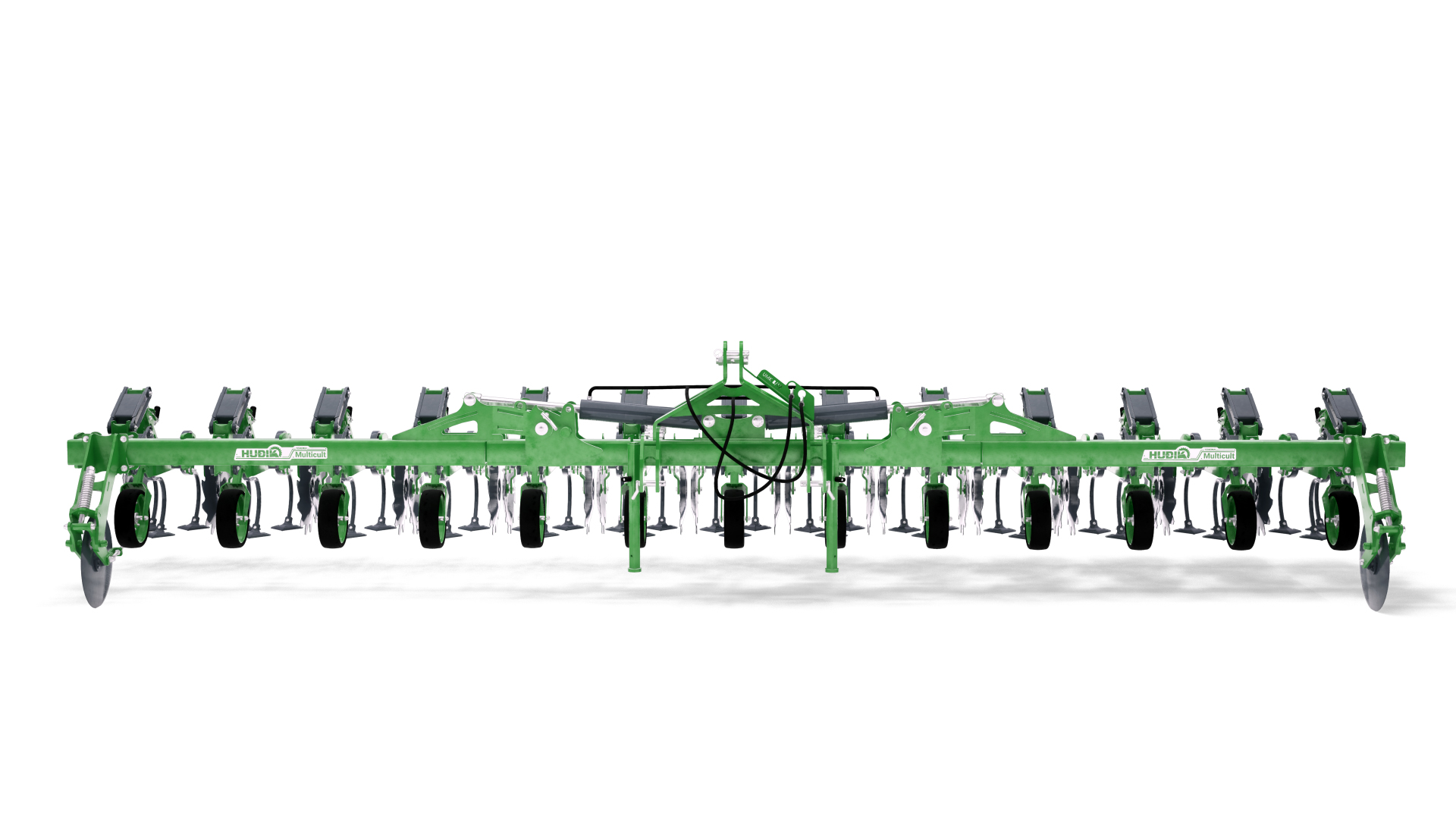

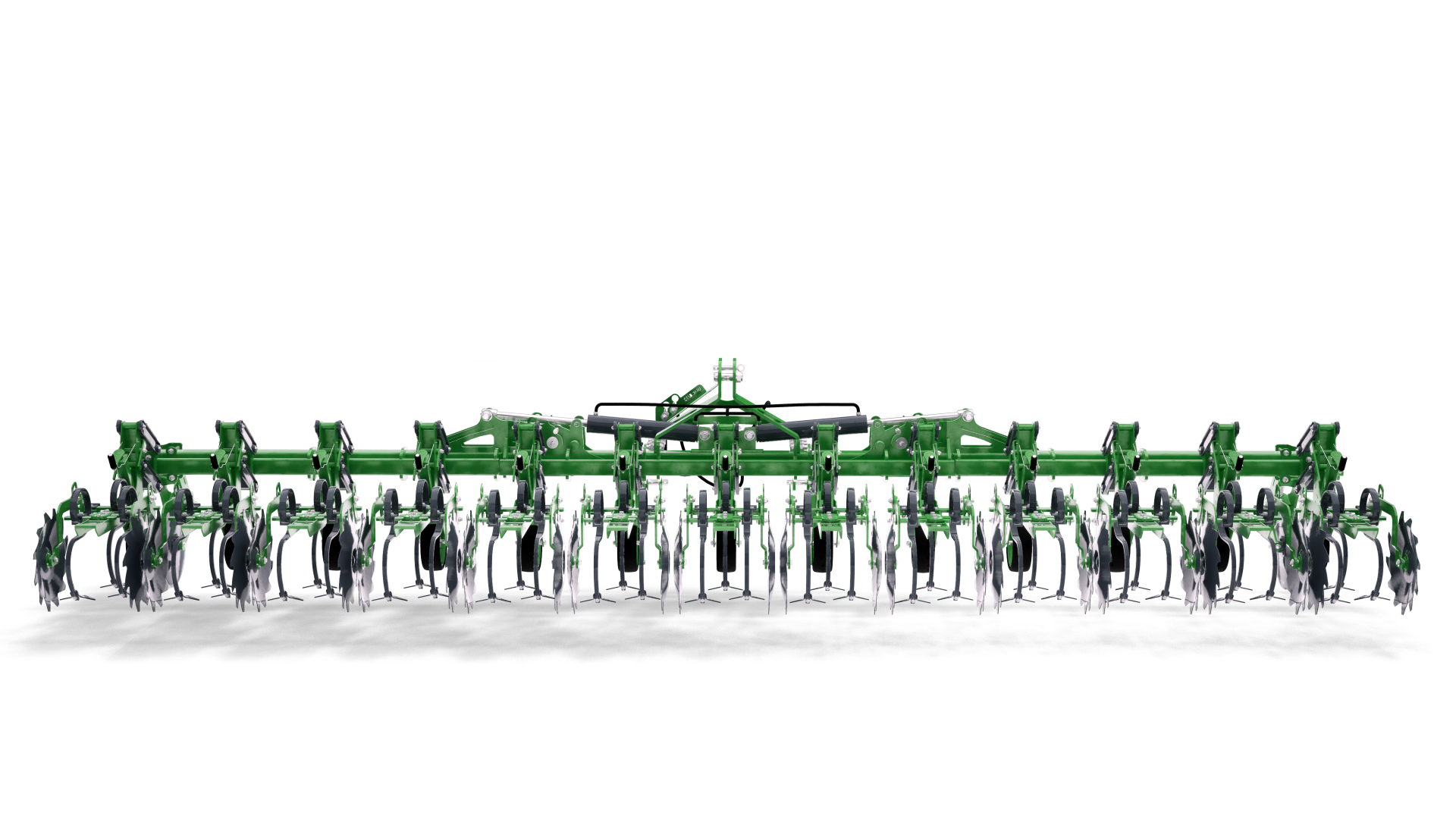

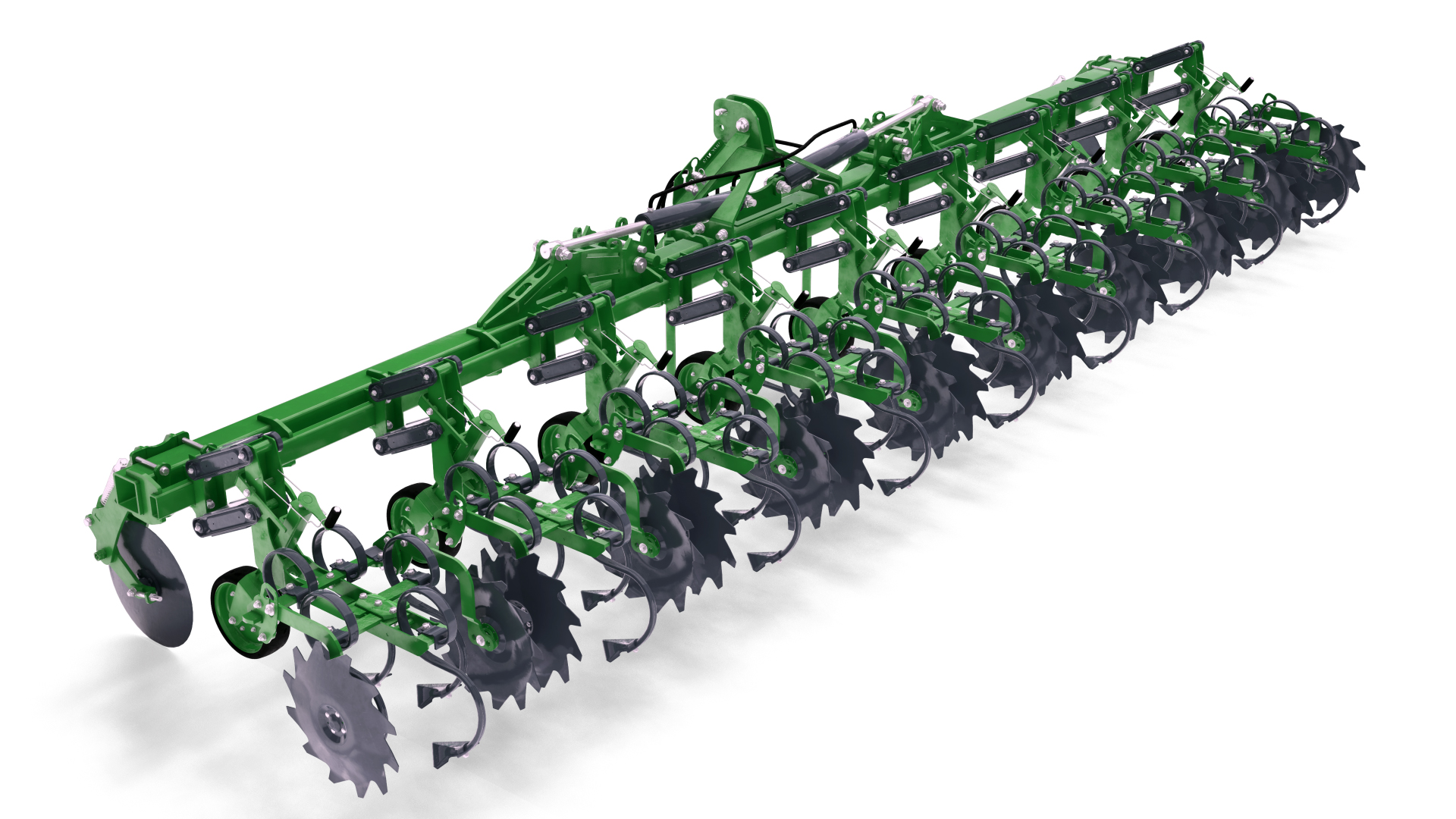

Cultivator

In recent years traditional tillage has been unfairly disregarded in favor of herbicides. With the growing acceptance of organic production and environmental protection, it is once again finding its rightful place. This is not only because of its beneficial effects on crops and the environment, but also due to the economic advantages of significant cost reduction.

Some of the advantages that support healthy plant growth, enhance yield, and lead to significant cost savings during production will be highlighted:

Specially designed for weed management in broad-row crops, this universal machine can handle various crops such as corn, turnips, sunflowers, soybeans, oilseed rape, legumes, sorghum, and vegetables.

Simplicity

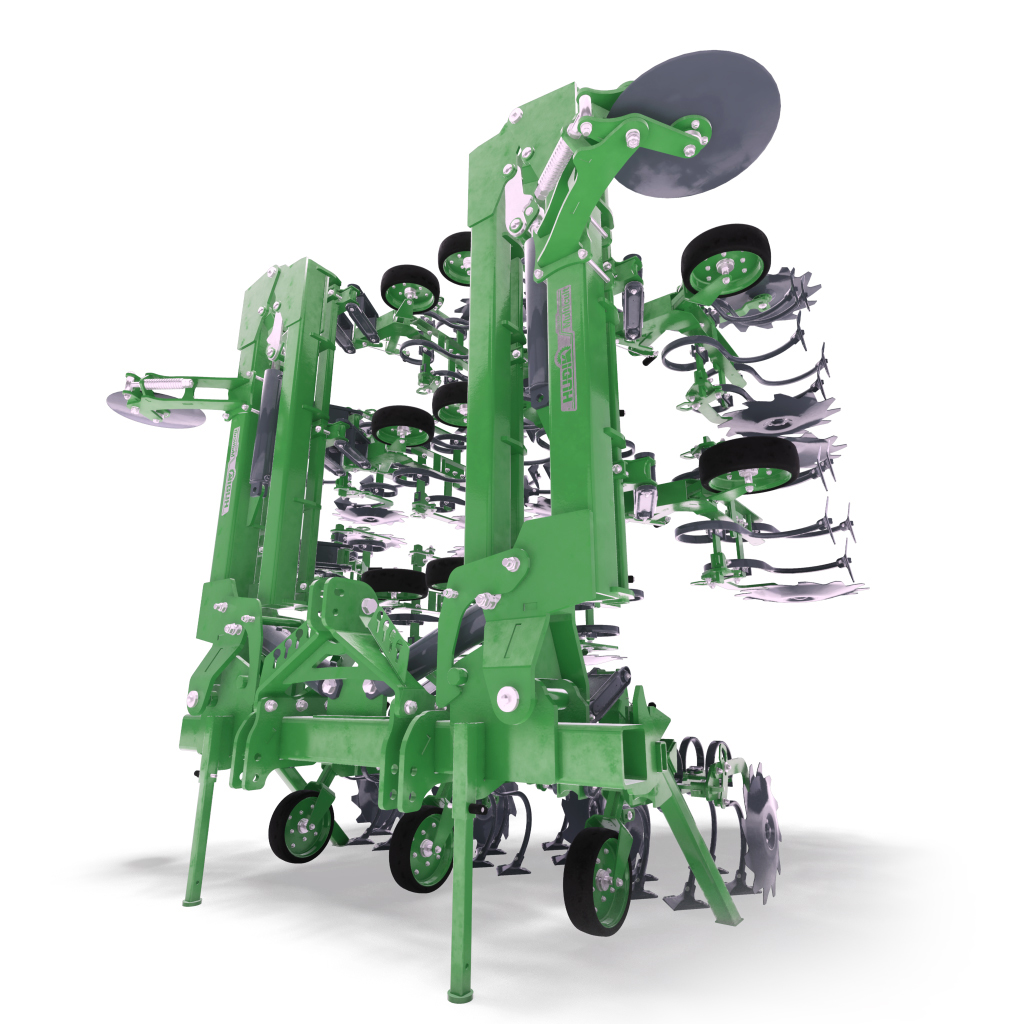

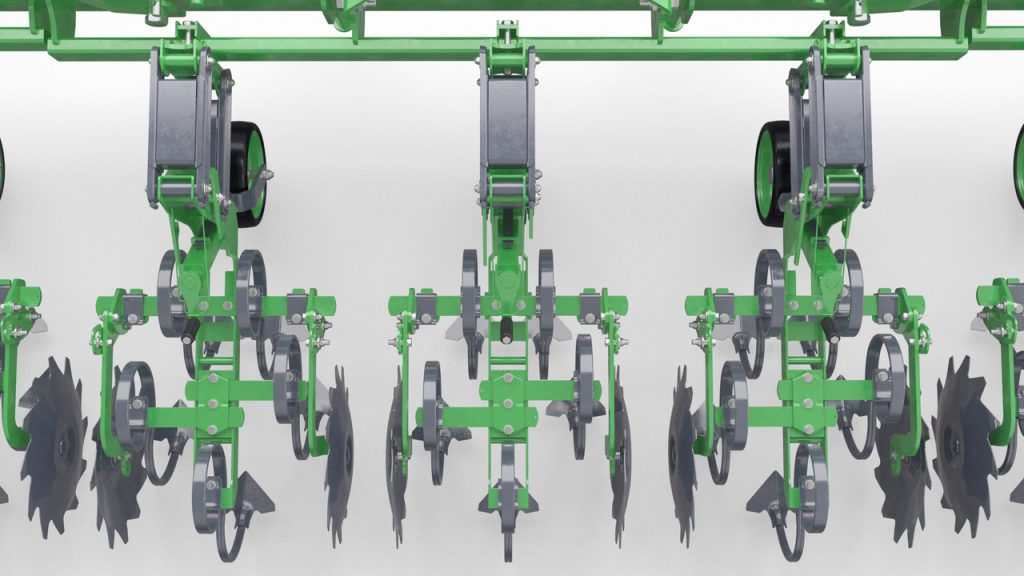

The cultivator remains precise on uneven ground and during tractor steering oscillations, thanks to the help of precise guide discs. With their advanced technology, they provide accurate row monitoring regardless of weed height, eliminating the need for costly camera systems.

Precision

Precise guide discs facilitate steering and ensure that the inter-row cultivator does not lose its precision on uneven ground and due to oscillations in tractor steering. They enable perfect row monitoring regardless of weed height without the need for an expensive investment in a camera row monitoring system.

Perfect precision in weeding

In conjunction with large toothed protection discs that ward off debris and potential damage to the plant's roots and stems thus tillage can be conducted even when crops are in their early stages, ensuring precise weed removal without risking harm to the crops.

Working height

The 65 cm maximum working height allows for usage even during the later stages of crop growth.

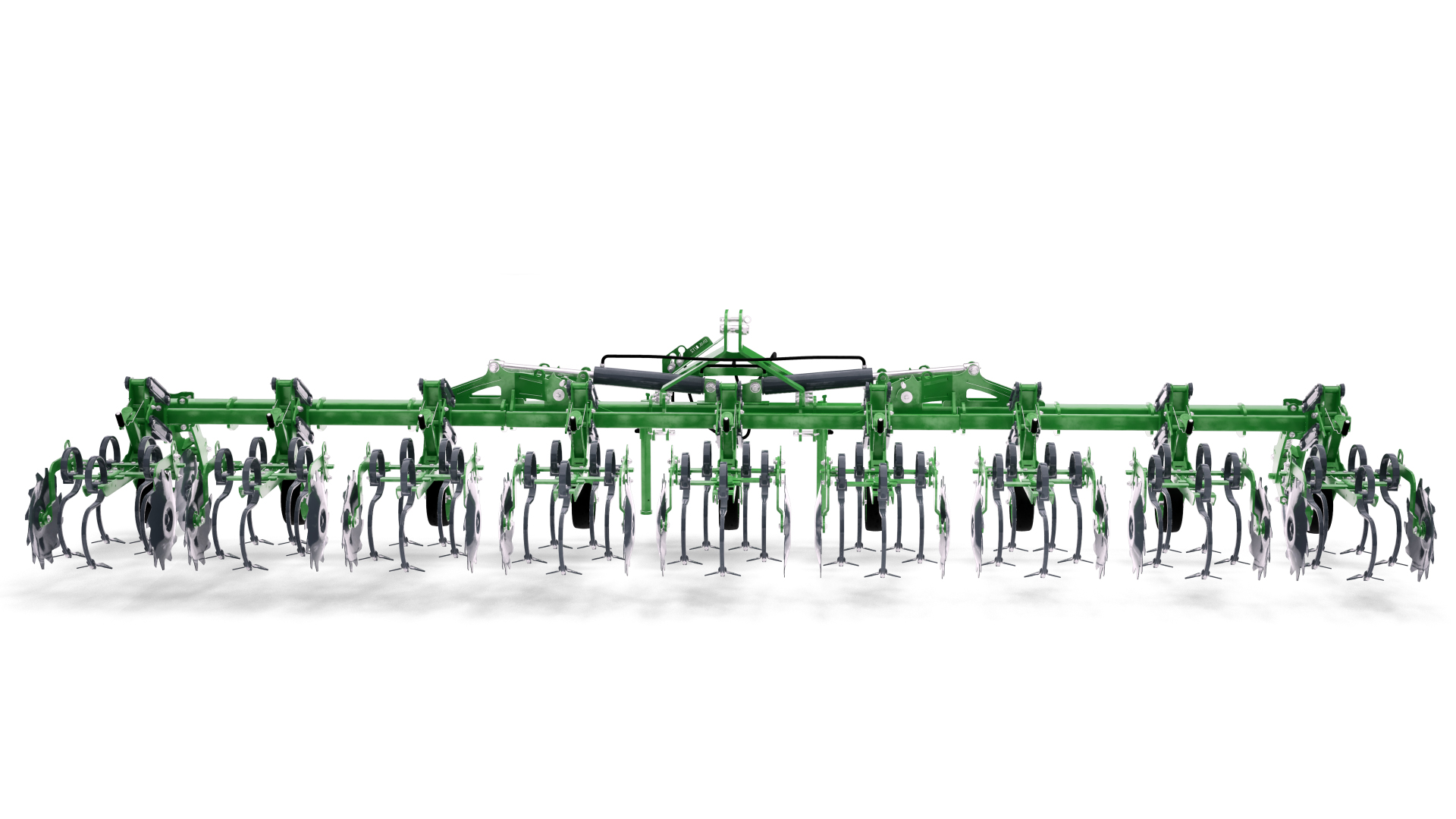

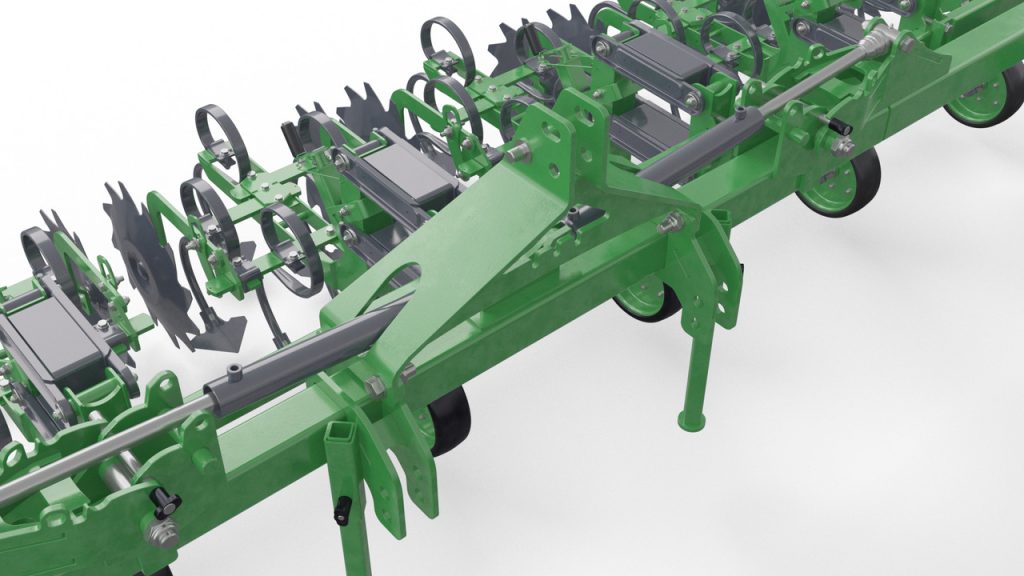

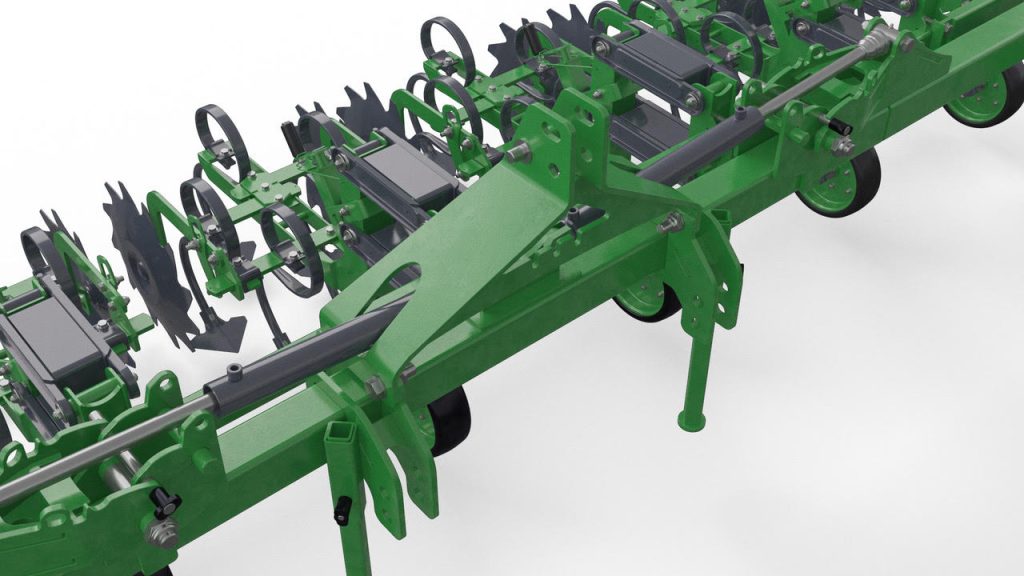

Cultivator with spring S-tines

The HUDJIK cultivator features spring S-tines and protection discs, allowing for fast and efficient soil cultivation between rows. After cutting the weeds at their roots, they are promptly removed and dried. This process not only preserves the soil structure, but also improves its aeration and loosens it. Maintaining a speed of 10-12 km/h is recommended for optimal performance. The cultivator's construction ensures accurate row tracking, even on rough ground. Every individual cultivation unit (row unit) operates independently, using its own wheel to maintain depth and parallelism. This ensures that the tines always stay at the correct depth. The bearings in wheels, discs, and oscillator mechanism are equipped with closed and permanently lubricated, eliminating the need for additional lubrication. This not only decreases maintenance expenses but also makes operation easier.'

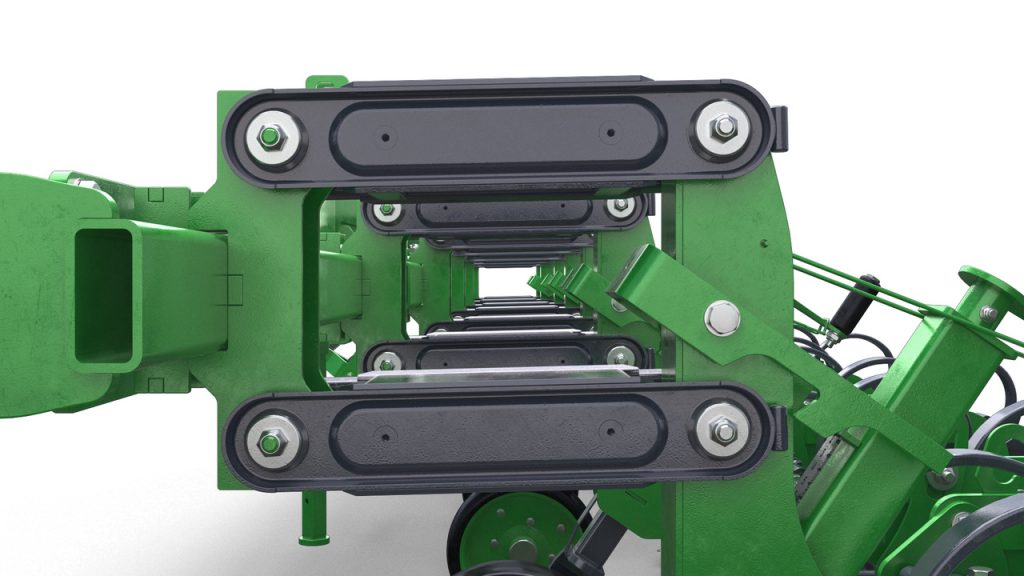

Construction with oscillatory mechanism

The oscillatory mechanism of HUDJIK inter-row cultivators is built with conical bearings, setting them apart from others. which feature guarantees accurate battery strokes, effortless movement, and long-lasting durability, eliminating the need for complex repairs caused by wear and tear.

Distance between hoes

Within a range of 55 cm, 3 hoes are active in a row, and beyond that, 5 hoes operate in parallel. The universal cultivator could be attached to the tractor in 3 different ways. The optimal adjustment of a connection is dependent on the tractor type, connection type, and connection category.

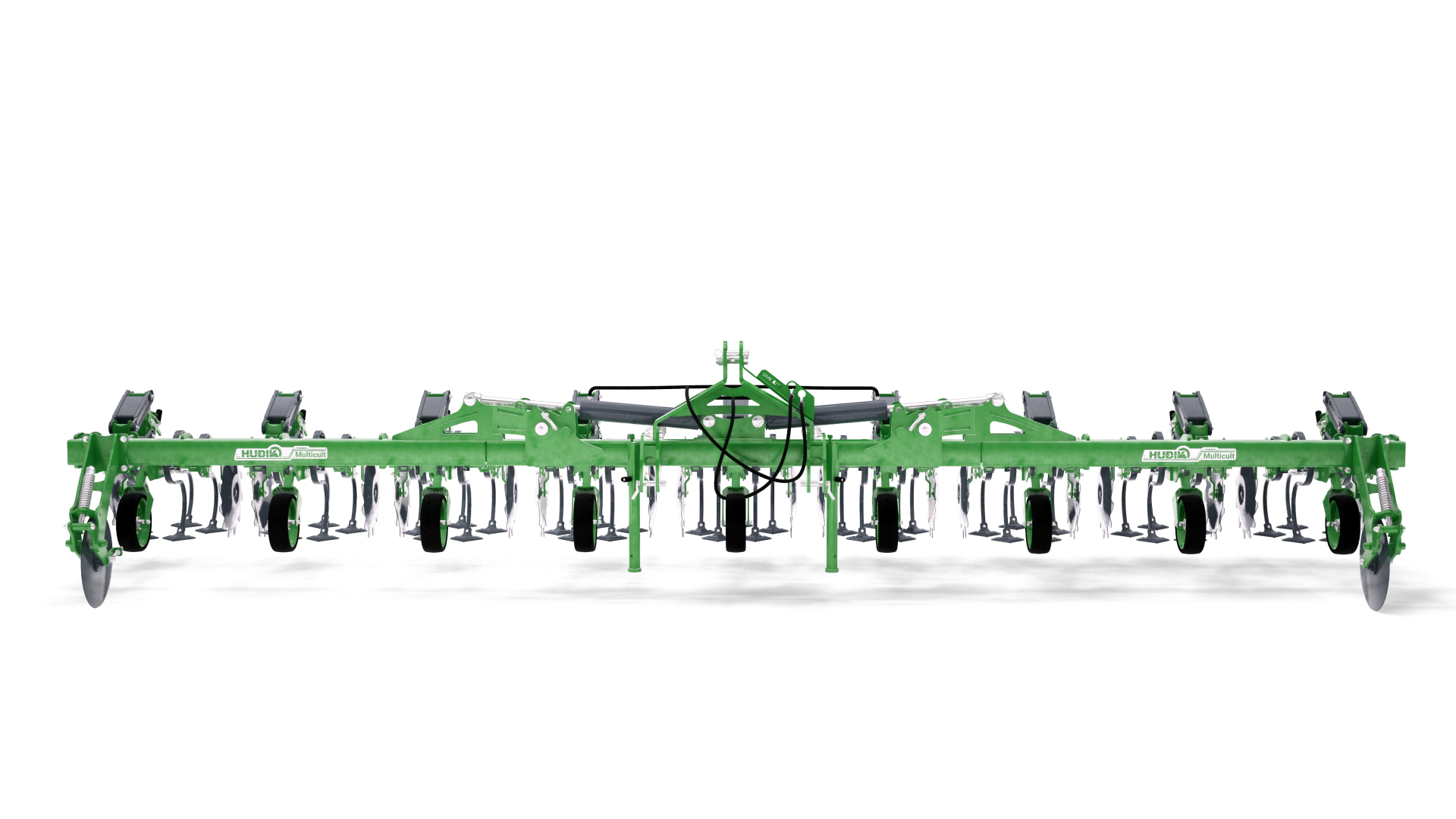

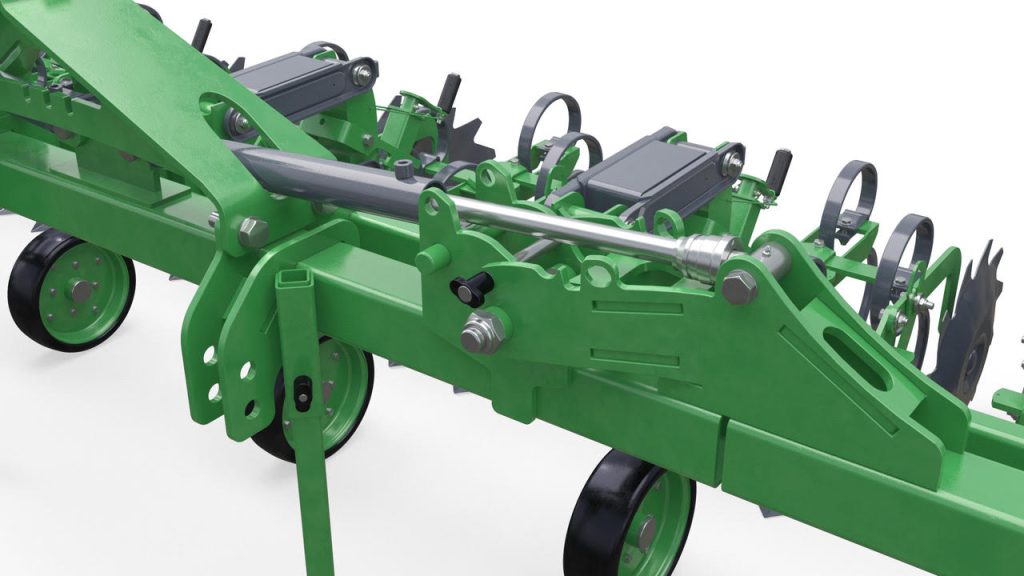

Cultivator with hydraulic folding

When the machine's working width exceeds 3 meters, HUDJIK cultivators are featured with a collapsible frame. Folding is done by a hydraulic cylinder controlled from the tractor cab.

Catalogue parts

| Characteristics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Types/subtypes of universal inter-row cultivator UMK | ||||||||||

| Beams | UMK-4 | UMK-6 | UMK-12 | UMK-18 | ||||||

| UMK-4K | UMK-6R | UMK-6K | UMK-7R | UMK-8R | UMK-8K | UMK-12R | UMK-12K | UMK-18R | ||

| Number of rows | 4 | 6 | 6 | 7 | 8 | 8 | 12 | 12 | 18 | |

| Minimum tractor power (kW/HP) | 30/40 | 40/55 | 40/55 | 40/55 | 40/55 | 50/70 | 70/95 | 88-120 | 88-120 | |

| Working width in the open state - max (cm) | 337 | 337 | 497 | 497 | 497 | 637 | 637 | 920 | 920 | |

| Approximate transport dimensions HxL (m) | 1.55x2.7 | 1.55x2.7 | 2.33x2.7 | 2.33x2.7 | 2.33x2.7 | 2.95x3.1 | 2.95x3.1 | 2.95x2.95 | 2.95x2.95 | |

| Approximate mass (kg) | 700 | 820 | 850 | 890 | 930 | 1020 | 1300 | - | - | |

|

Wing folding method Mechanical –M Hydraulic-H and number of hydraulic cylinders (pcs.) | M - | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 2 pcs | H 4 pcs | H 4 pcs | |

| Leading discs | - | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Number of middle sections with rubber wheel (pcs.) | 1 | 5 | 3 | 4 | 5 | 3 | 5 | 3 | 5 | |

| Number of middle sections with metal wheel (pcs.) | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Number of sections on the left beam (pcs.) | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 5 | 7 | |

| Number of sections on the right beam (pcs.) | 1 | 1 | 2 | 2 | 2 | 3 | 4 | 5 | 7 | |

| Number of elastic springs (pcs) | 31 | 19 | 31 | 22 | 25 | 41 | 37 | 61 | 55 | |

| Row width (cm) | 65-70-75-76.2 | 45-50 | 65-70-75-76.2 | 45-50 | 45-50 | 65-70-75-76.2 | 45-50 | 65-70-75-76.2 | 45-50 | |

| Operating speed (km/h) | 7-14 | |||||||||

Galerija